Subcategories

NEW PRODUCTS FOR FEBRUARY - CS9960 SPRAY SYSTEM

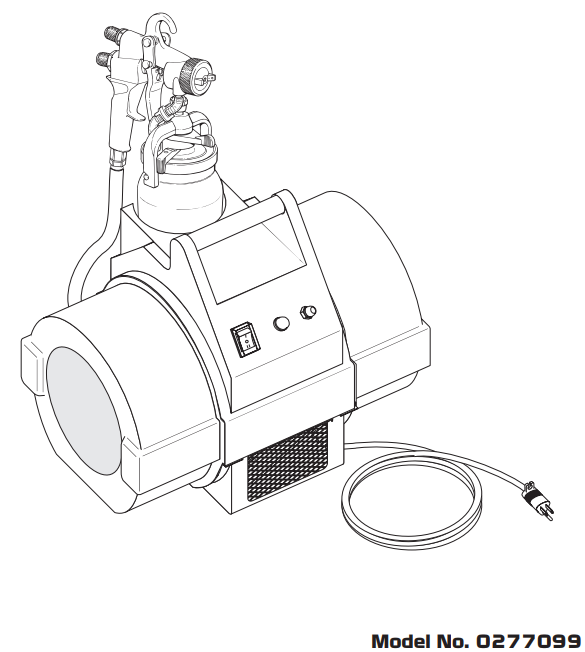

The CS9960 is a powerful HVLP (High Volume, Low Pressure) turbine-driven spray system built for fine-finish tasks, furniture, woodwork, and coatings requiring controlled atomization. Its 6-stage turbine delivers robust airflow and enough atomizing pressure (≈ 10 PSI) to spray heavier coatings, including multi-color materials and latex with minimal thinning. The complete system typically includes a turbine unit, air hoses, an HVLP spray gun (commonly a “Maxum II” 1-quart gun with #3 tip set), and necessary connectors and air filtration components.

Because it combines power and portability (the turbine unit weighs about 26 lbs) and a dual-filter airflow system, CS9960 is designed to offer professional-quality finishes while remaining workable for contractors and serious hobbyists.

The CS9960 Spray System parts well-suited for jobs including:

Because CS9960 relies on a dual-air filtration system to both cool the turbine and provide atomizing air, you should inspect filters regularly, ideally before each painting session. If the filter warning light is triggered or you notice reduced airflow, remove and clean or replace the filters. Consistent filter maintenance helps avoid overheating or damage to the turbine.

Uneven spray or sputtering can result from a clogged nozzle/air-cap, dirty or blocked fluid passages, worn tip set, or insufficient airflow (e.g., due to dirty filters). Clean or replace the nozzle/air cap and inspect fluid paths. Also, ensure correct tip selection for your paint viscosity, and verify hoses and connections are secure.

Yes, the 6-stage, ~10 PSI turbine of CS9960 is powerful enough to handle heavier coatings, including some latex paints or high-solids materials, often with little to no thinning. However, always follow paint manufacturer recommendations and test atomization on scrap material first to confirm an acceptable spray pattern.

After each use, flush and clean the spray gun, hoses, and fluid passages thoroughly. Remove residual paint, clean filters, dry all parts completely, and cover or store in a dry, dust-free environment. Periodically check seals, foam pads, and hoses for wear. This preventive maintenance greatly extends the lifespan of the system.

Common wear-and-replace items include air-filter sets, foam seals or dampening pads, hoses and quick-disconnect fittings, nozzles/air-caps (tip sets), and internal components like airflow switches or fan-noise foam/silencer parts. Keeping a spare filter set, nozzle/air cap, hose, and seals on hand is recommended, especially if you use the sprayer frequently.