Subcategories

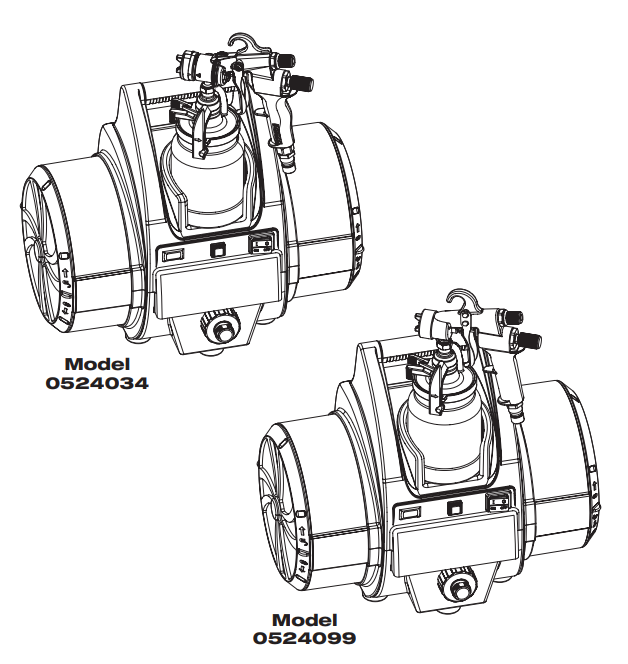

NEW PRODUCTS FOR FEBRUARY - CAPSPRAY 115 HVLP SPRAY SYSTEM

The CapSpray 115 is one of Titan’s top-end HVLP (High Volume / Low Pressure) turbine sprayers, engineered for heavy-duty and fine-finish jobs such as cabinetry, furniture, doors, trim, woodwork, cabinets, and other demanding coatings applications.

Clogged or dirty air filters (either atomising-air or cooling-air filters), which restrict airflow and reduce atomization quality. The built-in dirty-filter warning light signals when filters are compromised.

Solution: Unplug the turbine, remove filter covers, inspect pre-filters and fine filters; clean by tapping out debris, blowing with compressed air, or washing (if allowed), then ensure they are fully dry before reinstalling.

Filtration (atomising air filter + cooling air pre-filters) should be checked before each major job or whenever the “dirty-filter” warning light is activated. This ensures proper airflow and prevents overheating.

For structural parts (Upper Housing, Lower Housing, Main Assembly mounts), inspect periodically for cracks, loose fittings, or degraded seals, especially if the sprayer has been transported frequently or exposed to job-site stress. Any damage to housing can impair airflow or the protection of internal components.

Ensure all hose connections (30 ft air hose, 5 ft whip hose) are secure, and fittings are tight before each use. Loose fittings can cause air leaks, pressure loss, or inconsistent spray.

Keep the onboard toolbox organised, and inspect spare nozzles, needles, air caps and related tools for wear or damage. Use only compatible parts (projector sets #4, #5 for CapSpray 115) for optimal atomization.

The Lower Housing Assembly or Upper Housing Assembly protects internal components (turbine, electronics, cooling-air paths). Cracks, loose mounting points, or missing housing parts can reduce cooling airflow, leading to overheating or premature turbine wear.

If the sprayer is moved around a lot (job sites, transport), weakened housing may cause stress on internal components or wiring, risking malfunction or safety hazards.

Yes , neglecting filter maintenance of CapSpray 115 or housing/ventilation issues can lead to overheating of the turbine. Since the unit uses a dual-air system (atomising air + cooling air), blocked filters or restricted airflow reduce cooling air circulation. Over time, this can damage turbine internals or even cause operational failure.