Subcategories

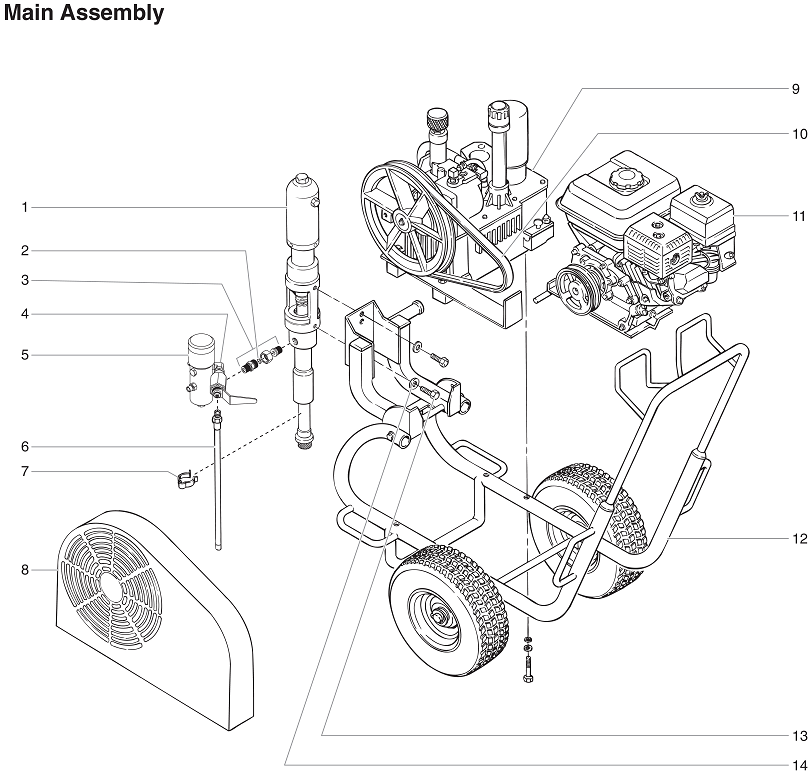

PowrTwin 12000XLT DI Main Assembly

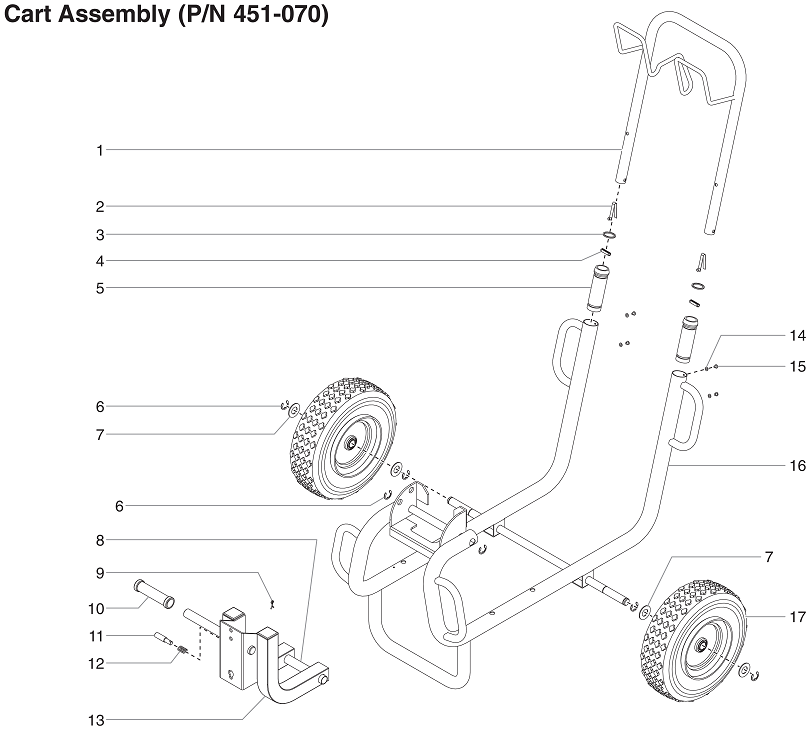

PowrTwin 12000XLT DI Cart Assembly

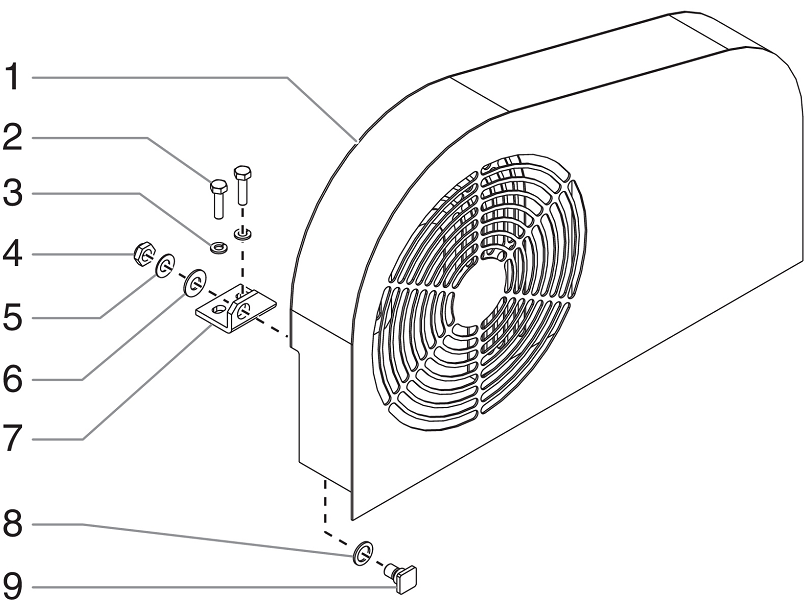

PowrTwin 12000XLT DI Belt Guard Assembly

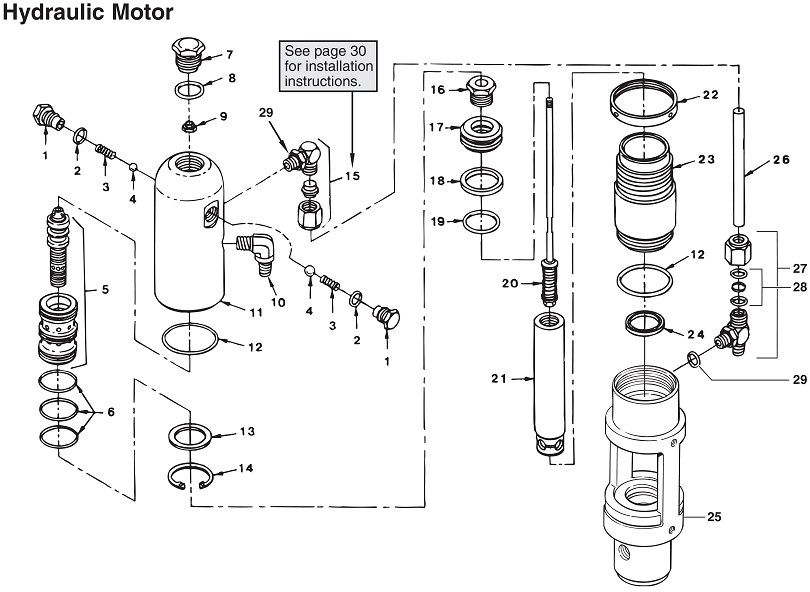

PowrTwin 12000XLT DI Hydraulic Motor

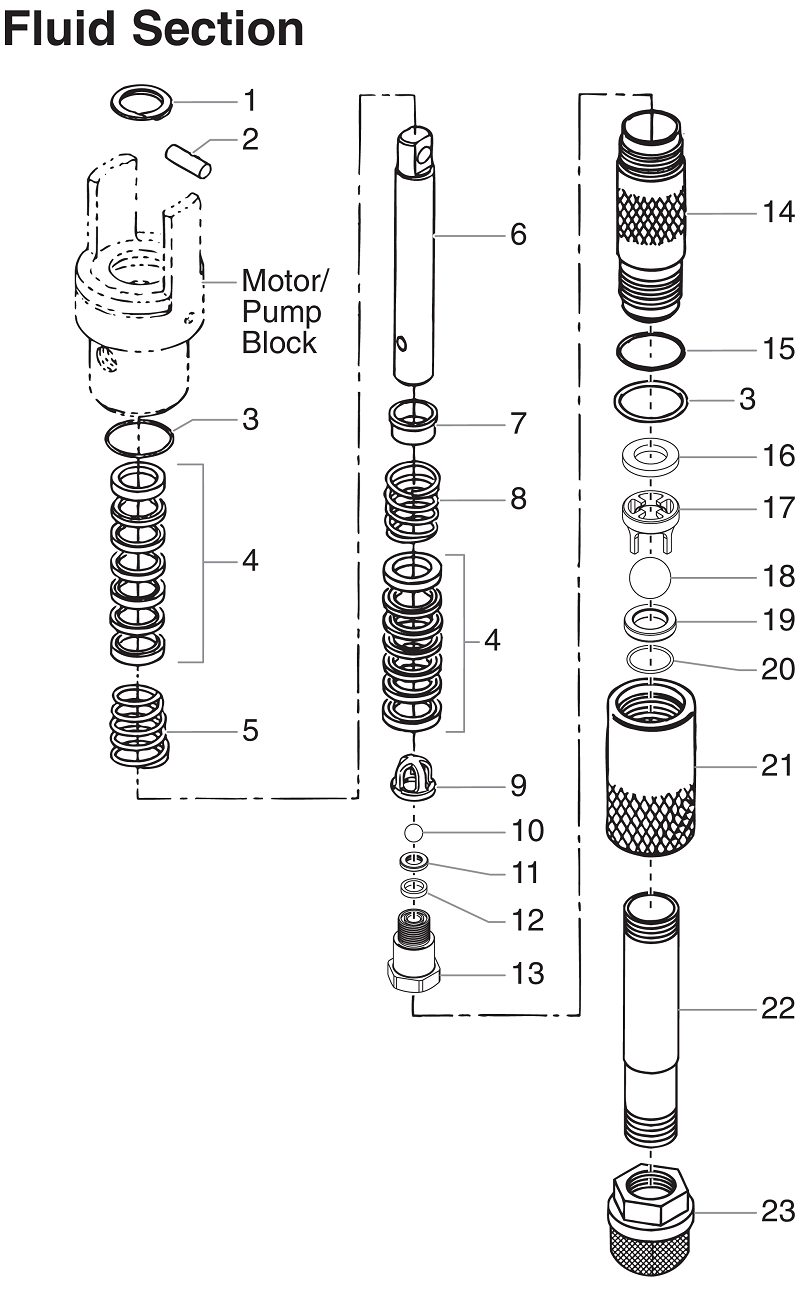

PowrTwin 12000XLT DI Fluid Section

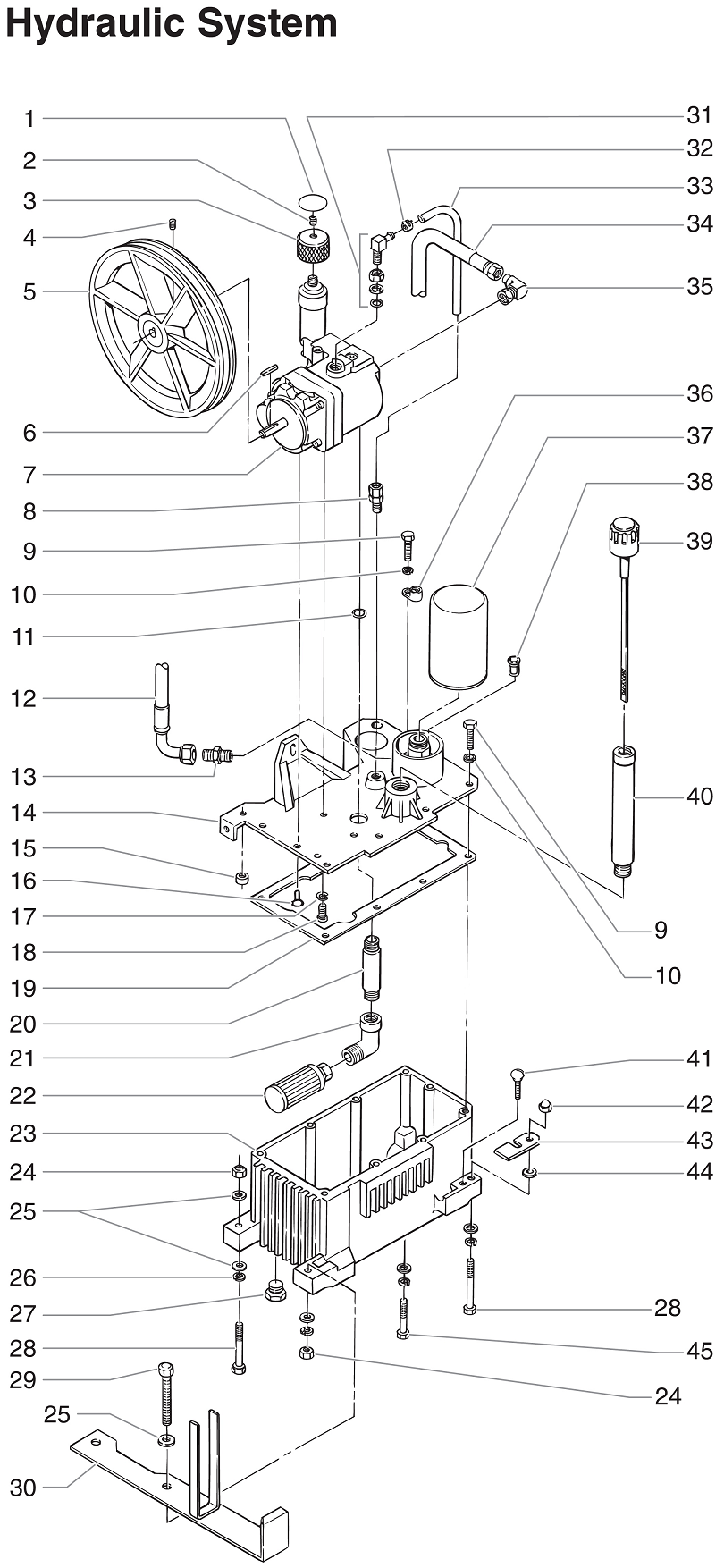

PowrTwin 12000XLT DI Hydraulic System

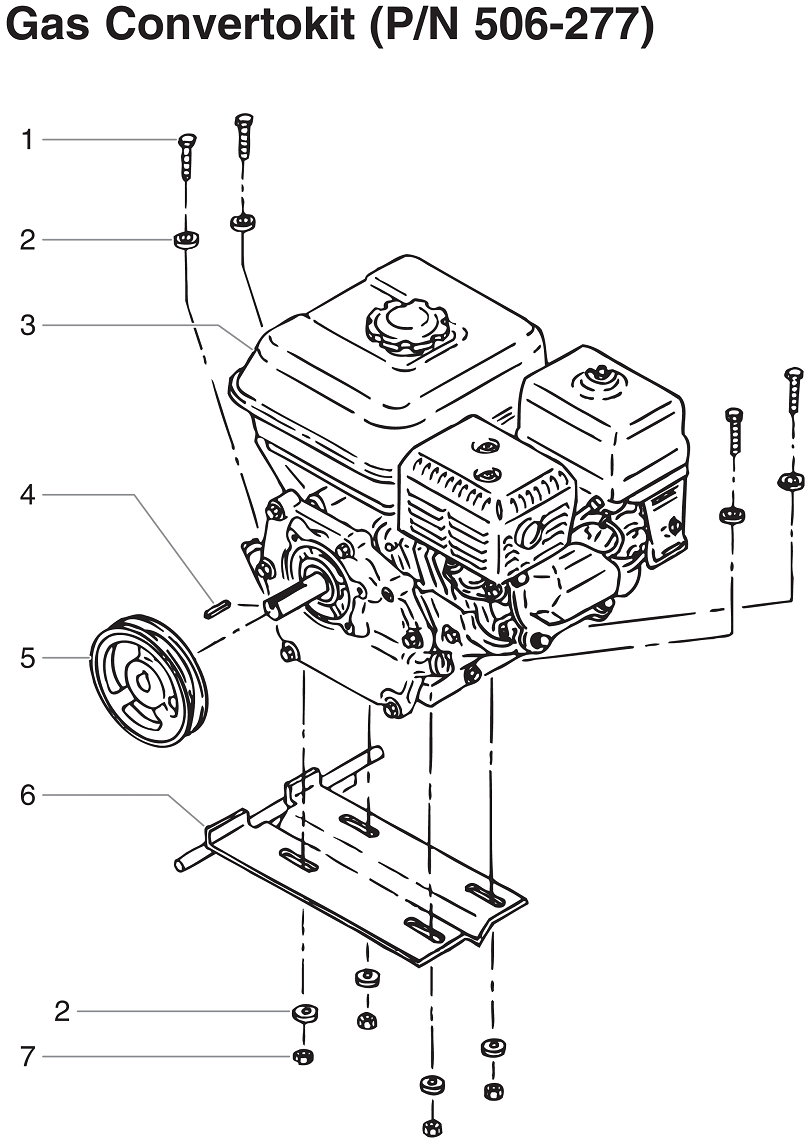

PowrTwin 12000XLT DI Gas Convertokit

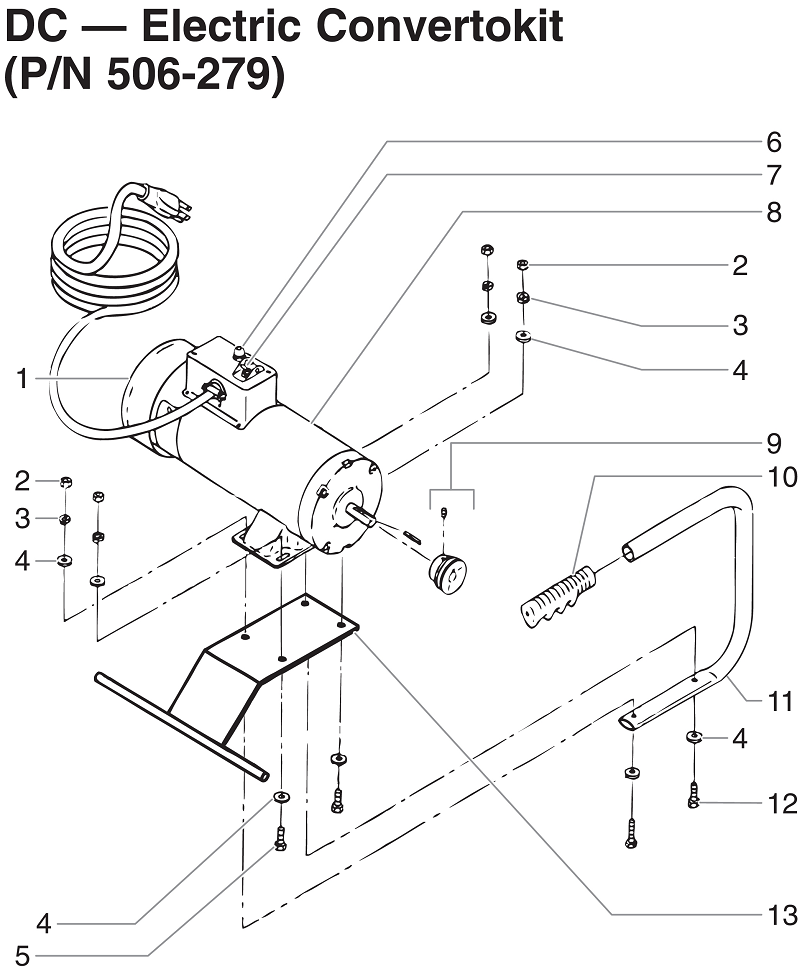

PowrTwin 12000XLT DC - DI Electric Convertokit

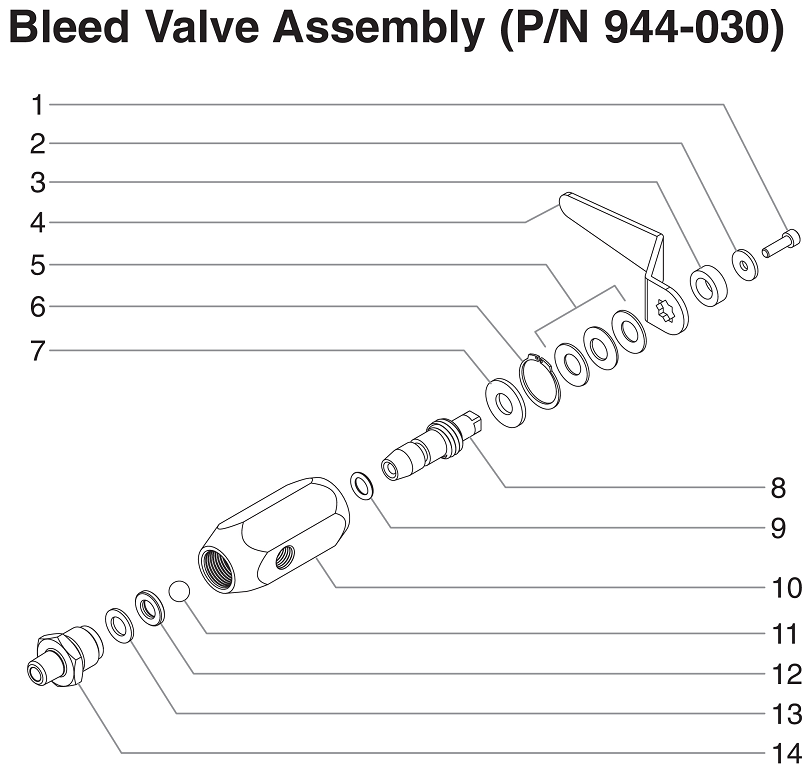

PowrTwin 12000XLT DI Bleed Valve Assembly

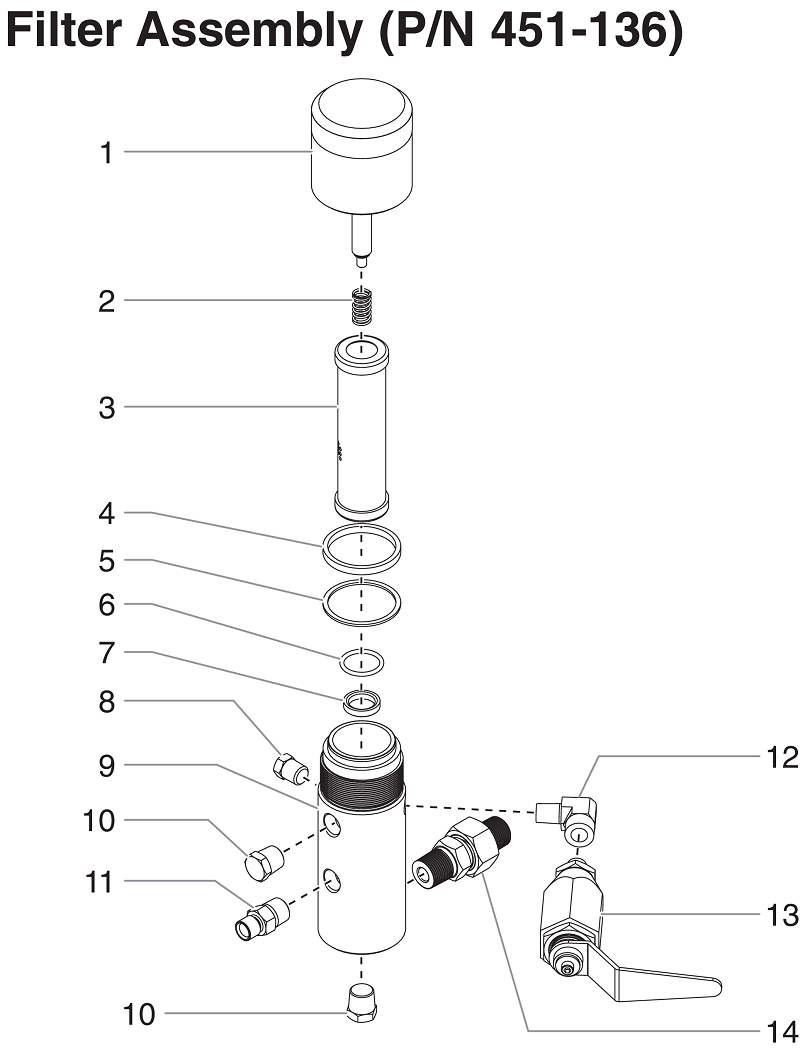

PowrTwin 12000XLT DI Filter Assembly

.png)

PowrTwin 12000 XLT DI Gun Manifold Assemblies (Optional)

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRTWIN 12000XLT DI

The PowrTwin 12000XLT is a high-performance, contractor-grade airless sprayer engineered for large-scale coating applications. Built for professionals who demand power, durability, and uninterrupted operation, this sprayer delivers consistent pressure and exceptional output across demanding commercial and industrial environments.

At AllTitanParts.com, we offer the complete range of PowrTwin 12000XLT parts, including the main assembly, hydraulic system, fluid section, gun manifold assemblies, bleed hose assembly, siphon hose assembly, filter assembly, cart assembly, belt guard assembly, and DC Electric Convertokit options. Whether you are replacing worn components, upgrading parts, or performing scheduled maintenance, our genuine PowrTwin 12000XLT parts ensure your sprayer continues to operate at peak performance.

The most frequently replaced PowrTwin 12000XLT parts include the fluid section seals, filter assembly elements, siphon hose, bleed valve assembly, and gun manifold components. Replacing these on time keeps the sprayer running efficiently and reduces breakdowns.

A pressure drop, an inconsistent spray pattern, or excessive pulsation usually indicates that the PowrTwin 12000XLT fluid section needs servicing or replacement. Regular inspection of packings, valves, and piston components helps prevent sudden failures.

Yes. The PowrTwin 12000XLT supports both the DC electric convertokit and the gas convertokit. Switching kits allow easy adaptation to different jobsite power requirements while maintaining full sprayer performance.

Daily cleaning of the siphon hose assembly, filter assembly, and gun manifold is recommended. Weekly inspection of the hydraulic system, belt guard assembly, and cart assembly helps identify early wear. Replace seals and filters according to usage and coating type.

Begin with the filter assembly—clogs are the most common cause. Next, inspect the siphon hose assembly for air leaks, the bleed valve assembly for blockage, and the fluid section for worn packings. Replacing these PowrTwin 12000XLT parts usually resolves pressure issues quickly.