Subcategories

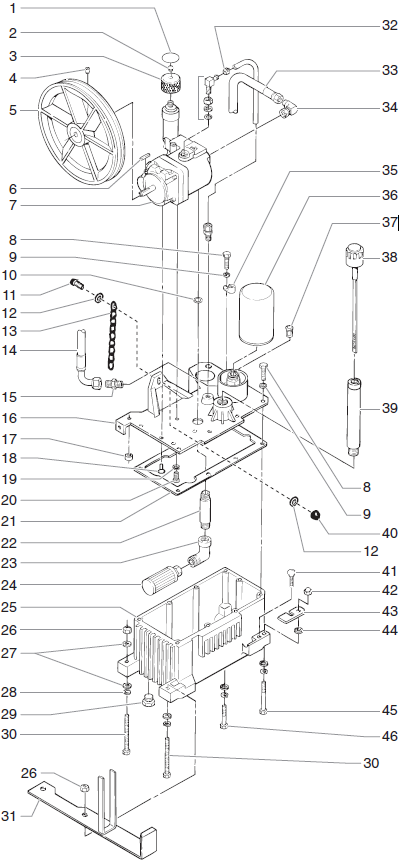

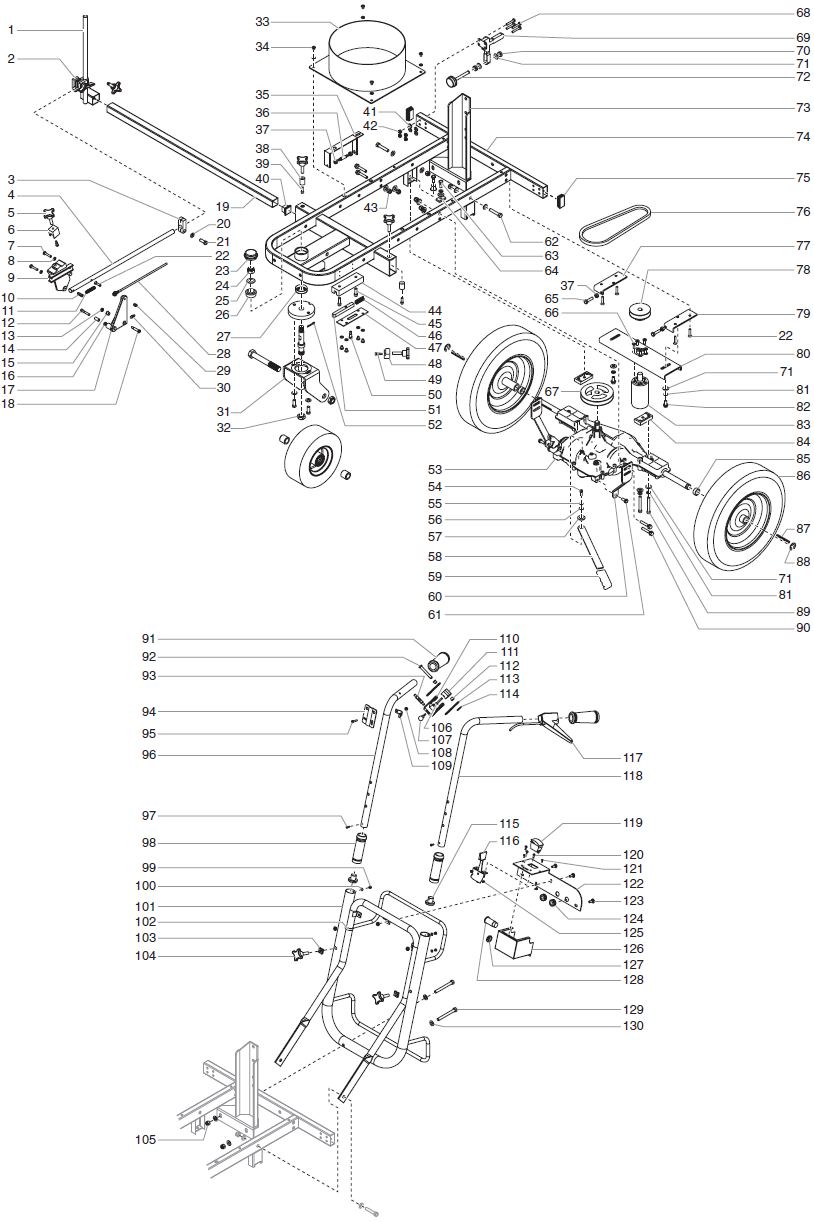

PowrLiner 9900XLT Main Assembly

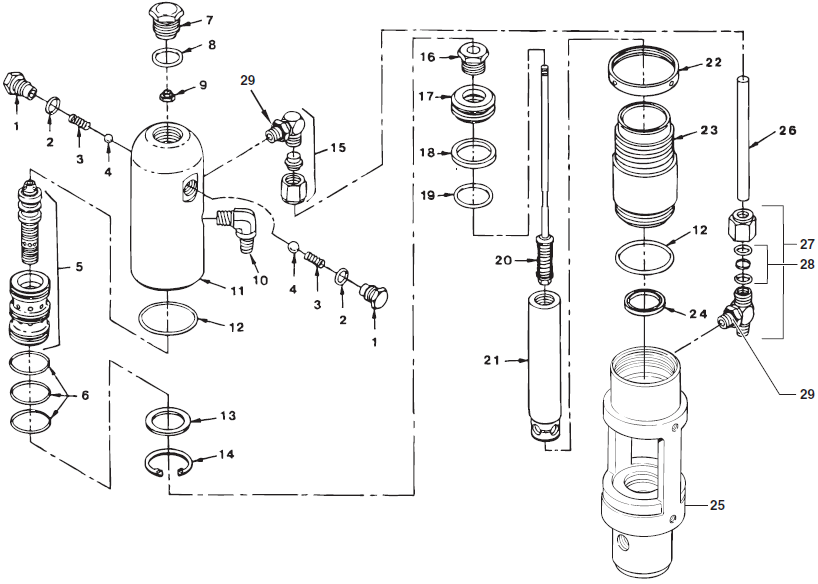

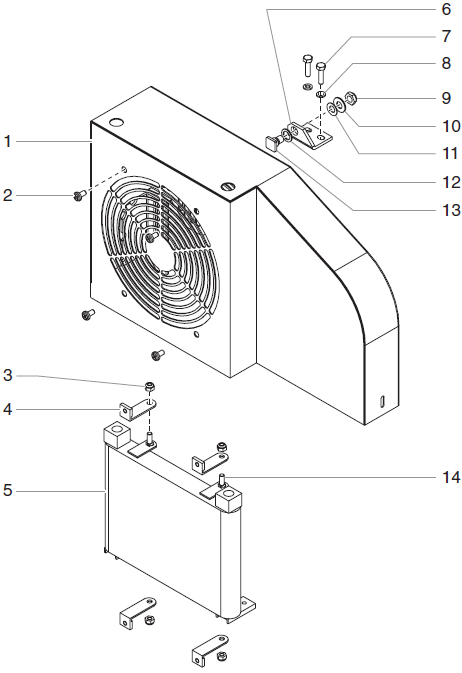

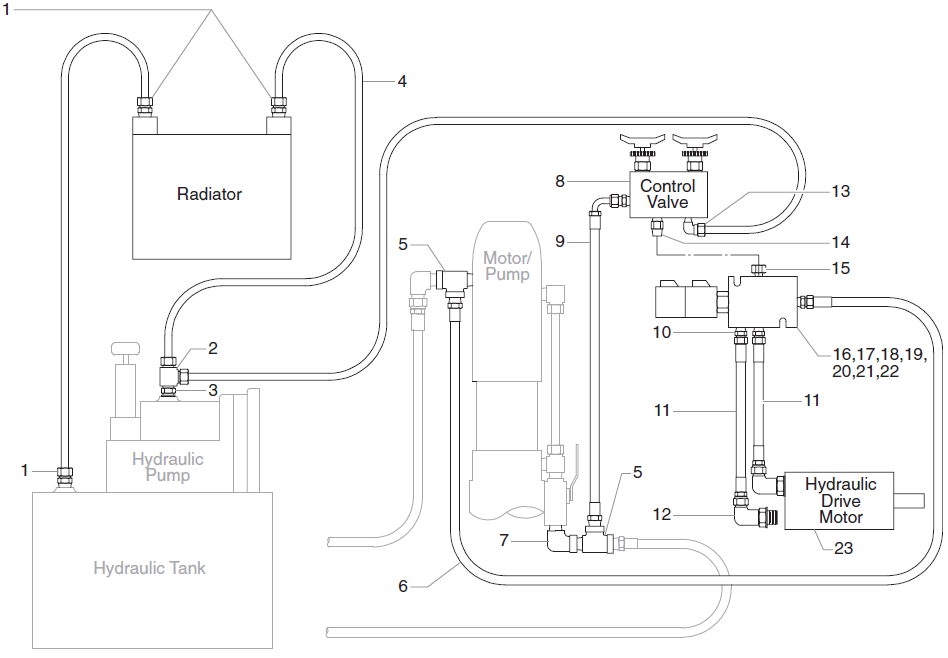

PowrLiner 9900XLT Hydraulic System Assembly

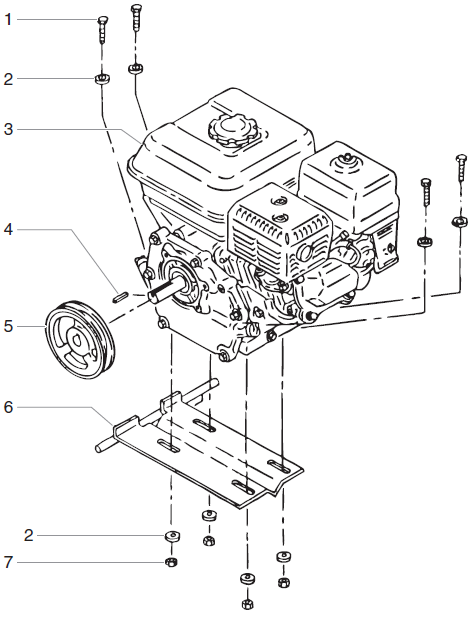

PowrLiner 9900XLT Gas Convertokit

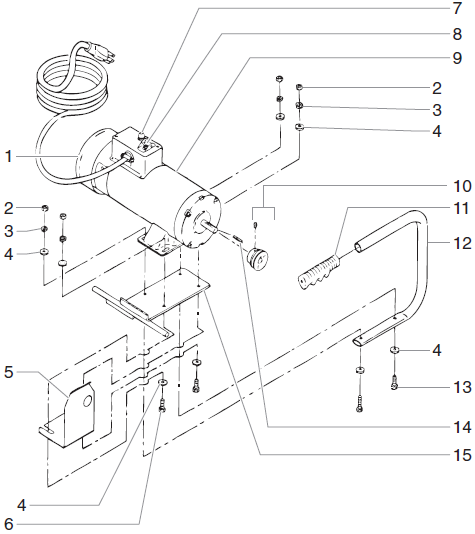

PowrLiner 9900XLT DC — Electric Convertokits

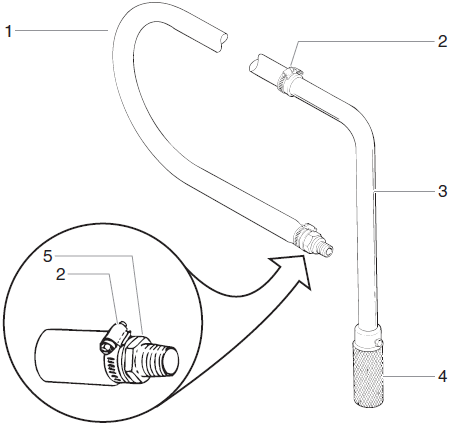

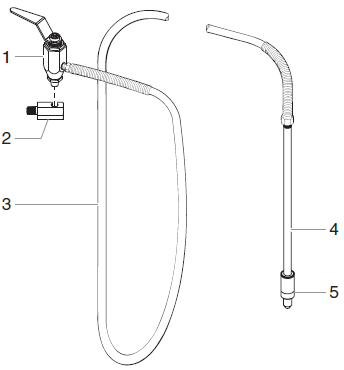

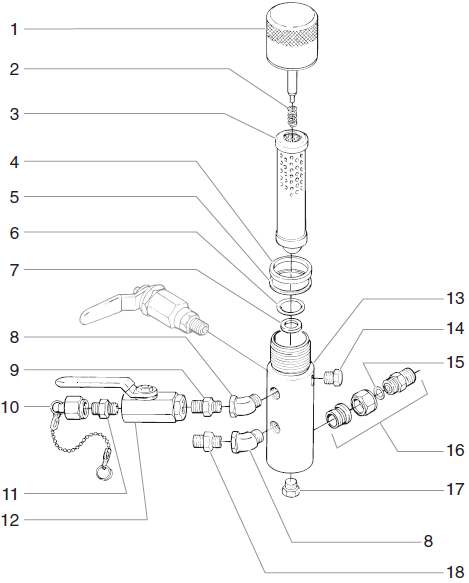

PowrLiner 9900XLT Siphon Hose Assembly

PowrLiner 9900XLT Bleed Hose Assembly with Valve

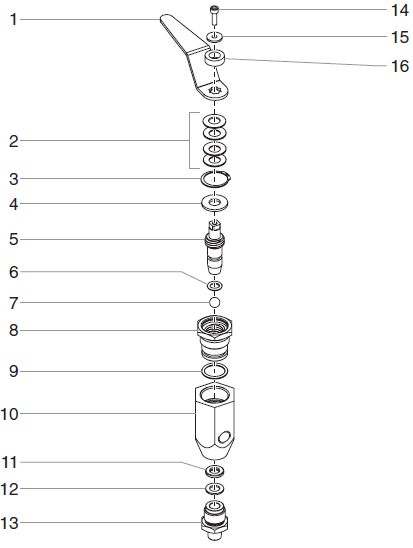

PowrLiner 9900XLT Bleed Valve Assembly

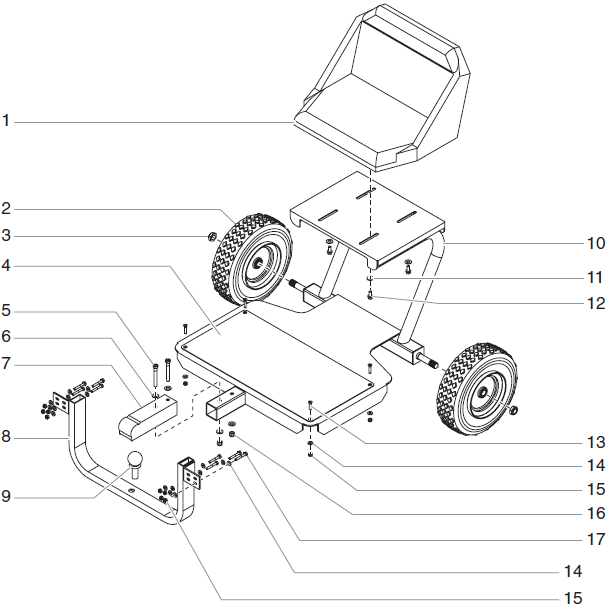

PowrLiner 9900XLT Cart Assembly (P/N 779-495)

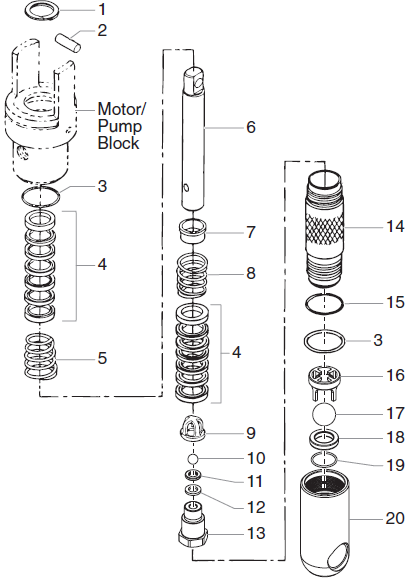

PowrLiner 9900XLT Hydraulic Motor

PowrLiner 9900XLT Fluid Section

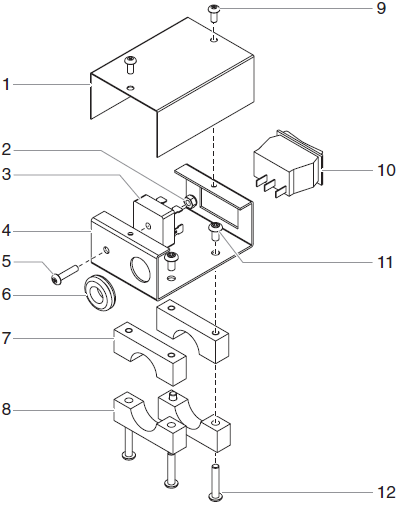

PowrLiner 9900XLT Filter Assembly

PowrLiner 9900XLT Belt Guard Assembly

PowrLiner 9900XLT Sulky Assembly (P/N 779-499)

PowrLiner 9900XLT Trigger Assembly

PowrLiner 9900XLT Hydraulic Hose System

PowrLiner 9900XLT Forward/Reverse Switch

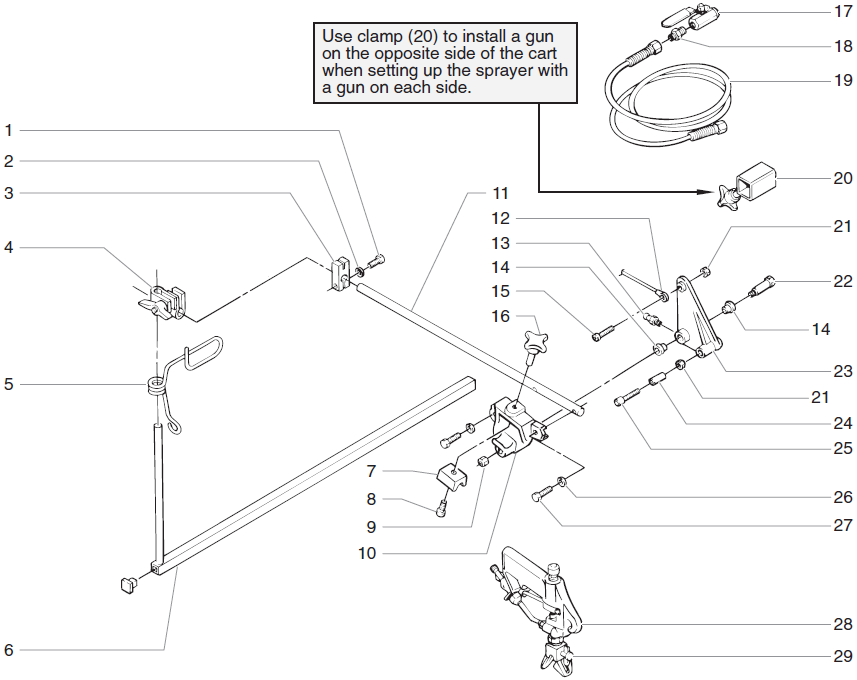

PowrLiner 9900XLT Second Gun Assembly

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 9900XLT

The PowrLiner 9900XLT is a professional-grade, ride-behind line striping machine engineered for the toughest and most extensive marking jobs. This hydraulic piston-driven system offers high output, robust construction, and precise control, ideal for jobs where speed, consistency, and reliability are essential.

The 9900XLT features a self-propelled PowrHandler drive system that helps operators cover large surfaces faster and with less effort than traditional walk-behind stripers. With versatile power options (gas, electric, or both) and contractor-level durability, the PowrLiner 9900XLT makes industrial-scale striping efficient and productive.

The PowrLiner 9900XLT is built for large-scale and professional marking tasks, including:

After each major stripping job, flush the paint hoses, siphon assemblies, and valves to prevent buildup. Regular cleaning helps maintain clear fluid paths and reduces the risk of clogs that can disrupt spray quality.

Pressure changes often come from partial clogs in filters or siphon hoses, worn valves, or paint contamination. Inspect and clean filters and siphon lines regularly to maintain stable pressure.

Check hydraulic fluid levels and hose connections periodically, and inspect the PowrHandler drive system for leaks or wear. Regular maintenance prevents performance loss and extends component life.

For gas-powered units, follow standard small engine care: check oil levels, replace or clean air filters, and inspect spark plugs. Clean any dust or paint overspray from engine components to avoid heat build-up.

The front caster and drive transaxle control steering and traction. Debris buildup or worn bearings can affect tracking accuracy. Regularly inspect and clean these parts to ensure straight and accurate line striping at all speeds.