Subcategories

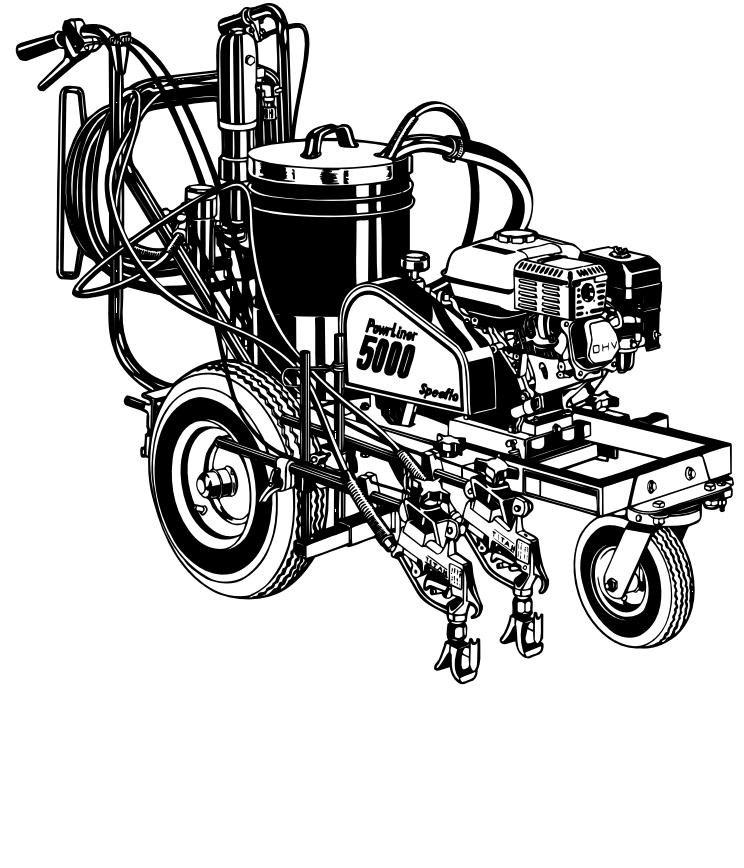

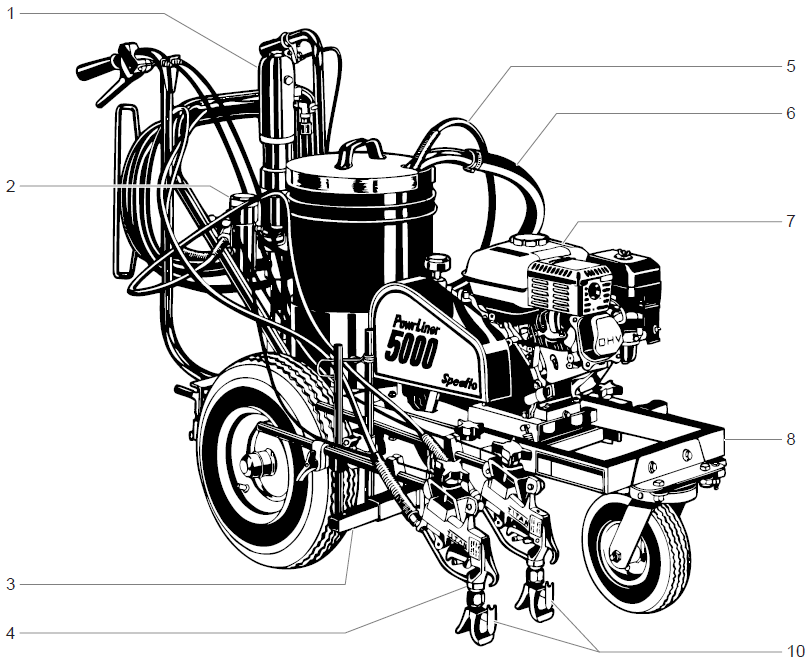

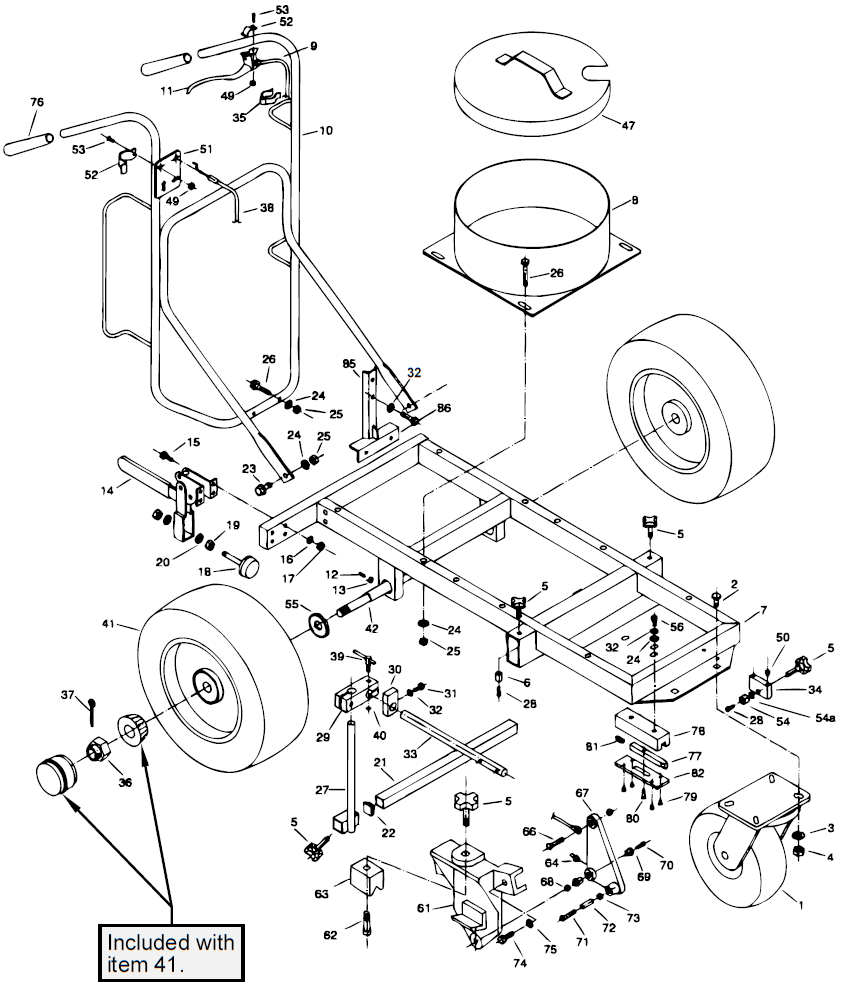

PowrLiner 5000 Main Assembly — Gas Model

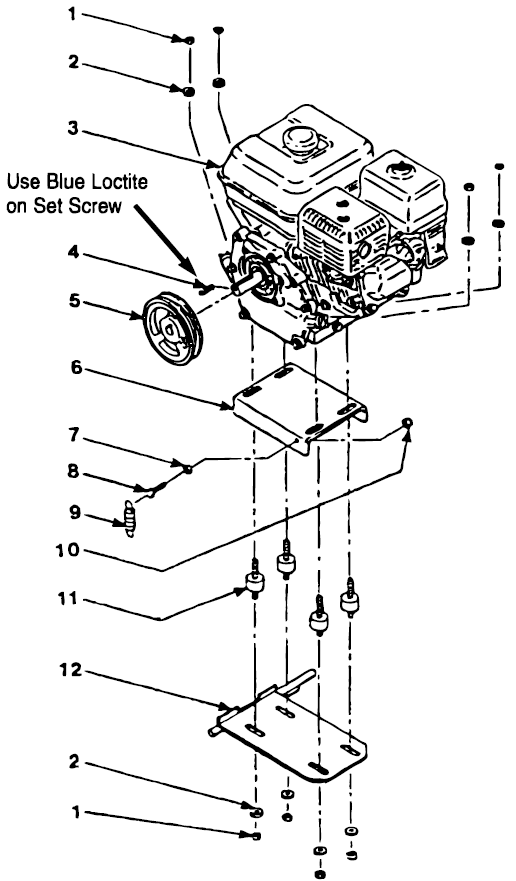

PowrLiner 5000 Gas Convertokits (P/N 506-102)

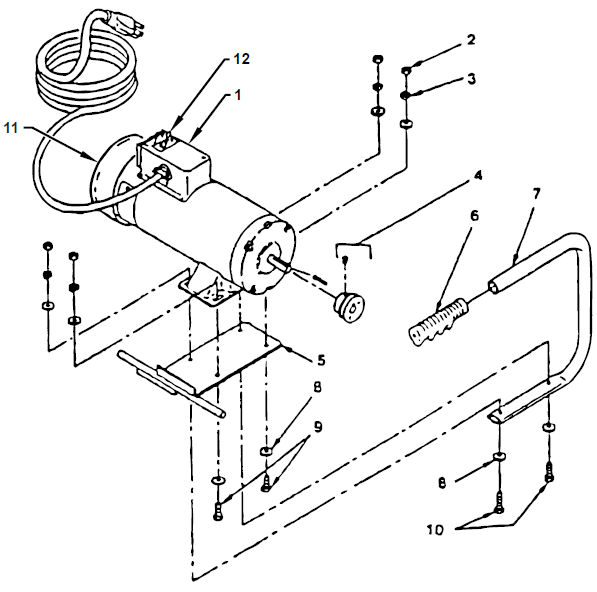

PowrLiner 5000 DC — Electric Convertokit

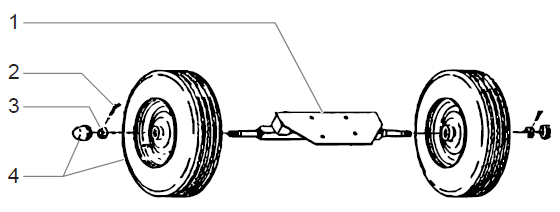

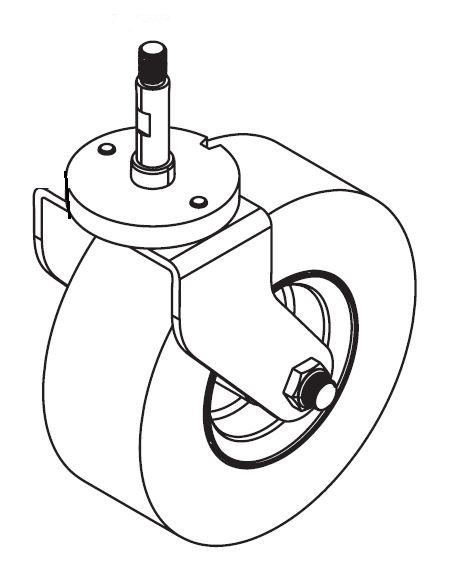

PowrLiner 5000 Cart Assembly (P/N 759-001)

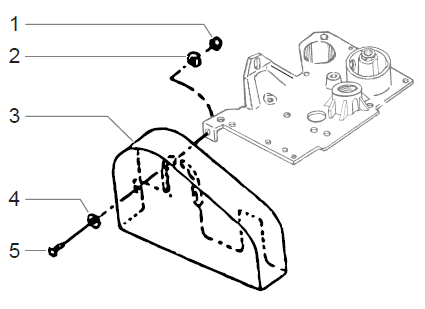

PowrLiner 5000 Belt Guard Assembly

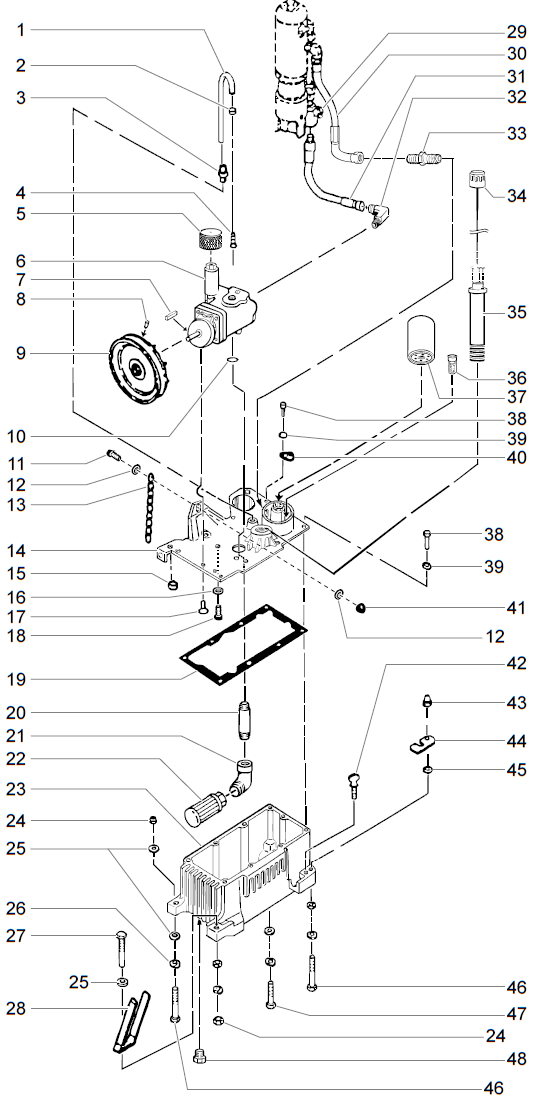

PowrLiner 5000 Hydraulic System

PowrLiner 5000 Hydraulic Motor

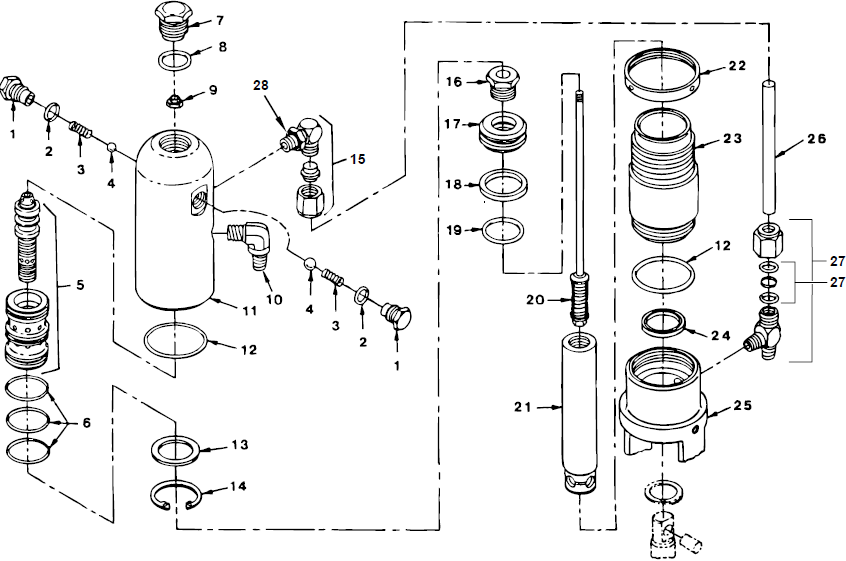

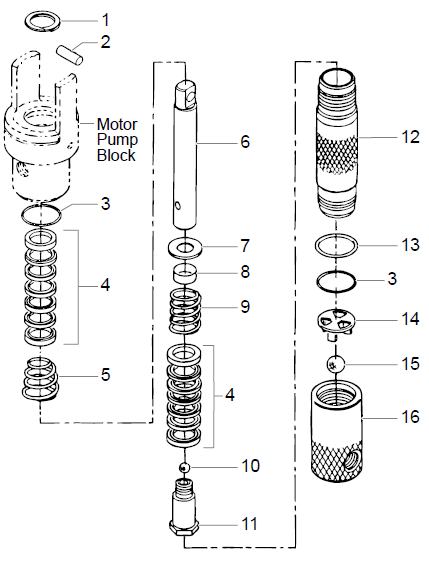

PowrLiner 5000 Fluid Pump

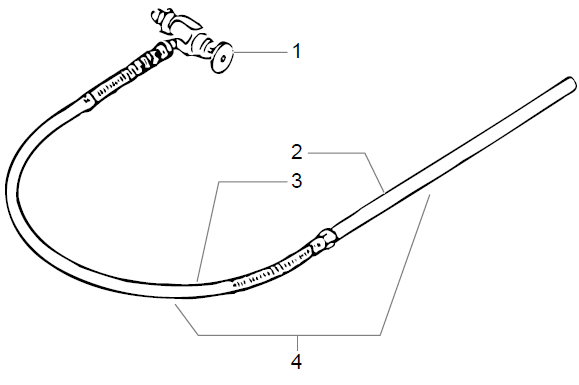

PowrLiner 5000 Bleed Line Assembly with Valve (P/N 840-212)

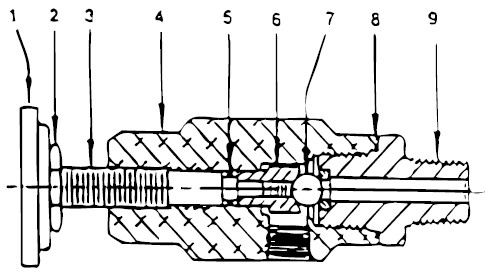

PowrLiner 5000 Bleed Valve Assembly (P/N 944-620)

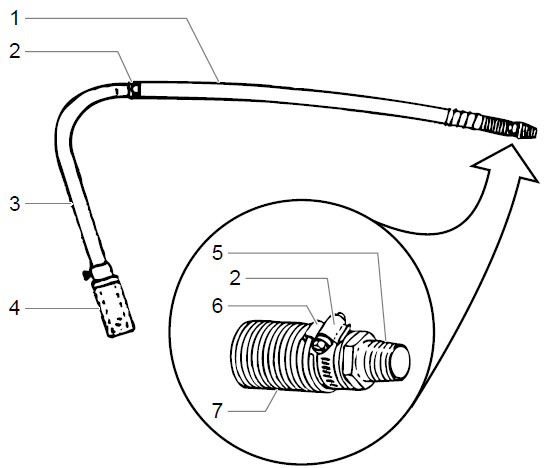

PowrLiner 5000 Siphon Hose Assembly

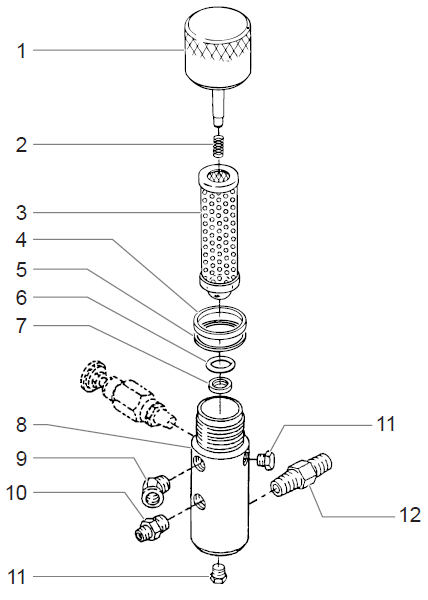

PowrLiner 5000 930 Outlet Manifold Filter Assembly with Check Valve

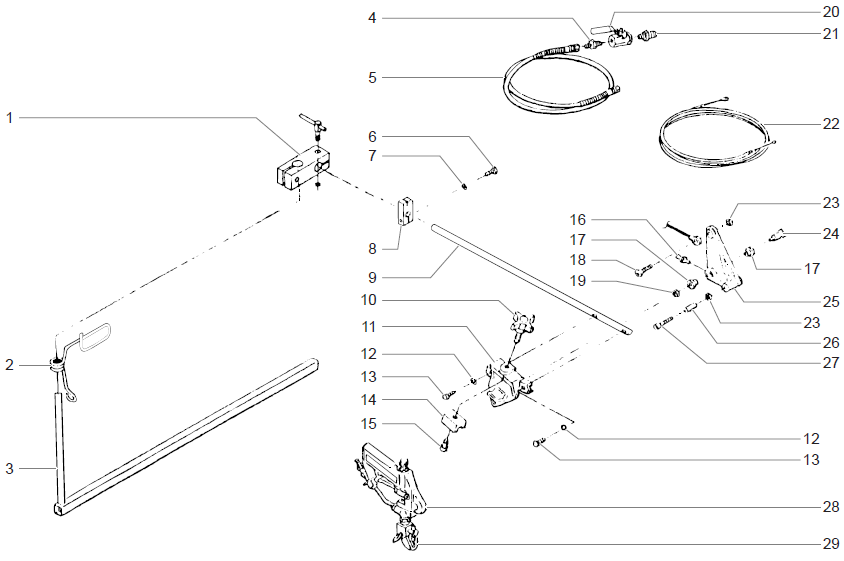

PowrLiner 5000 Second Gun Assembly Complete (P/N 759-038)

PowrLiner 5000 Trigger Assembly

PowrLiner 5000 Line Pointer (P/N 424-620)

PowrLiner 5000 Athletic Field Marking Kit/Turf Kit

Accessories

NEW PRODUCTS FOR FEBRUARY - POWRLINER 5000

The PowrLiner 5000 is a heavy-duty, professional-grade airless line-striping machine designed to handle demanding road-marking, parking lot striping, athletic field marking, and other large-scale pavement marking jobs. Built with rugged construction and advanced fluid pump technology, the 5000 delivers high-pressure performance with excellent material delivery, giving contractors both flexibility and reliability for frequent, high-volume striping work. Its design supports either gas converto kits or electric operation, offering versatility whether you are working outdoors or in environments where electricity is preferred or required.

Thanks to its robust hydraulic drive and durable pump design, the PowrLiner 5000 stands out for long-term use with minimal maintenance, even under heavy-duty conditions.

The PowrLiner 5000 is suitable for a wide variety of professional striping and coating tasks, including:

The PowrLiner 5000 supports a wide range of airless-processable materials, including latex and water-based paints, thick coatings, primers, anti-corrosive coatings, and other heavy or viscous materials. However, always verify compatibility with the coating manufacturer before application.

Using the electric motor (instead of gas) can offer quieter operation, lower emissions, and suitability for indoor or enclosed job sites. It also avoids issues related to gasoline availability. The PowrLiner 5000 allows flexible switching between gas and electric, based on job requirements.

Its hard-chrome plated piston and cylinder rod resist abrasion and corrosion; self-adjusting packings and tungsten-carbide valve seats extend packing and valve life; the robust pump design reduces wear and minimizes maintenance intervals making the unit dependable for heavy-duty, frequent use.

Ensure coatings are properly filtered and, if needed, diluted per manufacturer guidelines. Stir coatings carefully to avoid air bubbles. Use the recommended hoses, tips, and maintain the pressure within the unit’s operating range (up to 3300 PSI) for best atomization and line quality.

While the 5000 is capable of handling small jobs, its heavy-duty build and hydraulic motor system are optimized for medium to large-scale or frequent striping work. For very small or occasional jobs, lighter models may be more convenient, but if you desire long-term durability and versatility, the 5000 remains a robust choice.