Subcategories

NEW PRODUCTS FOR FEBRUARY - IMPACT X 440 AIRLESS SPRAYER

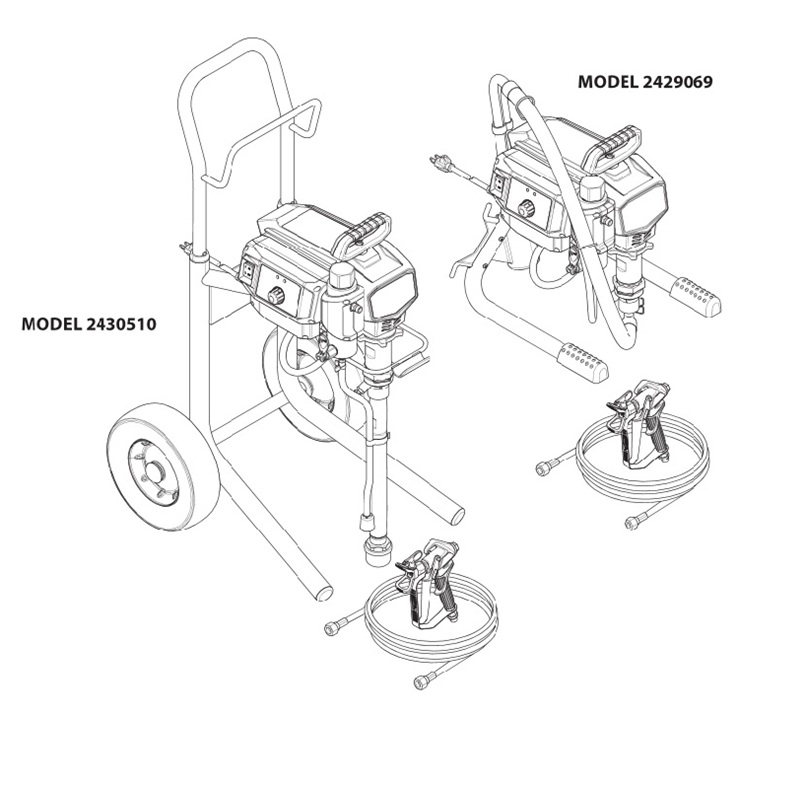

For professional painters who need accuracy and efficiency, the Impact X 440 Airless Paint sprayer is a strong and dependable instrument. Maintaining vital parts like the Impact X 440 Main Assembly Parts and Impact X 440 Cart Assembly Parts is key to keeping it operating at its peak. To keep your sprayer operating at its best, AllTitanParts.com provides a wide range of authentic replacement parts. By using high-quality parts, you can prolong the equipment's lifespan and avoid needless malfunctions. Using high-quality OEM components helps prolong the life of your Titan 440 airless sprayer and reduces downtime caused by malfunctions.

The pump, motor, and pressure control system are essential parts of the Impact X 440 Main Assembly Parts that cooperate to provide a uniform, smooth spray. To guarantee continuous high performance, replace any worn-out parts with authentic parts from AllTitanParts.com. Furthermore, the Impact X 440 Cart Assembly Parts are crucial for stability and mobility, which facilitates the sprayer's transportation between job locations. Efficiency and usability are maintained when these components are kept in excellent condition. Professionals trust us for OEM Titan parts to maintain and repair their equipment, whether it’s the Titan 440 impact paint sprayer, Titan 440 Impact X, or even the Titan Impact 440 parts diagram.

We make it easy to identify and acquire the appropriate Impact X 440 Airless Sprayer components at AllTitanParts.com. From titan 440 manual references to titan 440 paint sprayer parts diagrams, our large inventory ensures you get exactly what you need. To maintain your sprayer functioning like new, visit our website right now!

|

Name |

Model No |

Weight |

|

IMPACT X 440 SKID |

2429069 |

30 lbs |

|

IMPACT X 440 HIGH RIDER |

2430510 |

54 lbs. |

|

MAX. DELIVERY |

0.54 GPM | 2.04 LPM |

|

MAX OPERATING PRESSURE |

3300 psi | 22.8 MPa |

|

MAX TIP SIZE - 1 GUN - ELECTRIC |

0.023" |

|

RECOMMENDED GALLONS PER WEEK |

50-100 |

|

MOTOR |

1.2 hp Duralife HE Brushless |

|

ITEMS INCLUDED |

RX-80 Gun, 517 HEA Tip, 1/4" x 50' Airless Hose |

FAQs:

The Drive or Fluid Section & Motor Assembly is what powers the sprayer and maintains consistent pressure for smooth spray performance. Over time, wear on components like packings, pistons, or the motor can reduce output and affect finish quality.

Using genuine OEM parts ensures compatibility and integrity of the assembly helping preserve maximum pressure (up to 3,300 psi) and efficient operation.

For the Impact X 440 Filter Assembly Parts & Manifold Assembly, checking and cleaning the manifold filter regularly is key. A vertical‐filter housing design helps reduce cleanup time and uses less flush fluid. Inspect for clogs or wear: if coatings build up or flow slows down, replace filters to avoid spray defects, pressure drop or premature wear of the fluid section.

The Impact X 440 is designed for professional applications: small-to-medium commercial work, interior/exterior painting, and coatings of low to medium viscosity. Some key specs: max delivery around 0.54 GPM (≈2.04 L/min), max tip size around 0.023", and max operating pressure up to 3,300 psi.

When selecting parts (drive assembly,suction set, filters, hoses, tips) you want those rated for this pressure and flow — using undersized or lower rated components can lead to performance issues or damage.

If you notice pressure droop, inconsistent spray pattern or finish defects, check the following: