Subcategories

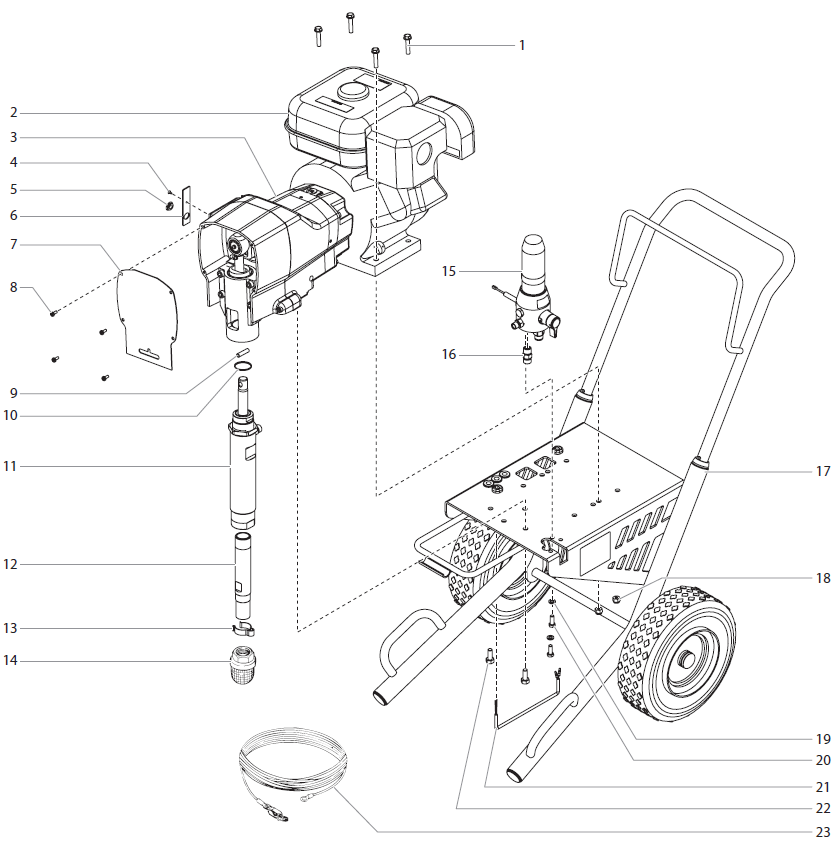

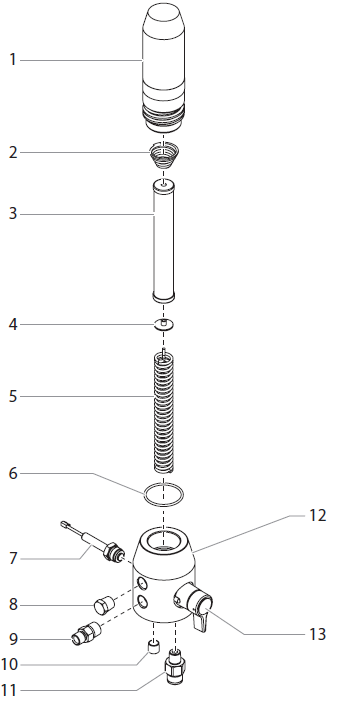

Advantage GPX 130 Main Assembly Parts

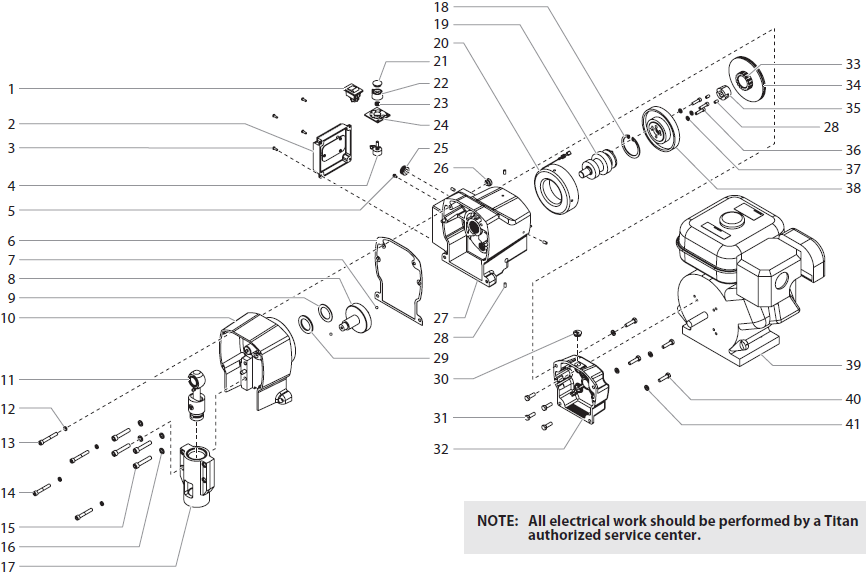

Advantage GPX 130 Drive Assembly Parts

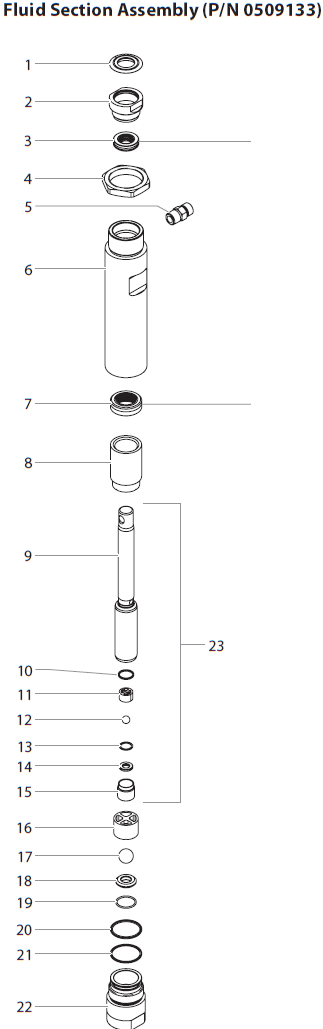

Advantage GPX 130 Fluid Section Assembly Parts (P/N 0509133)

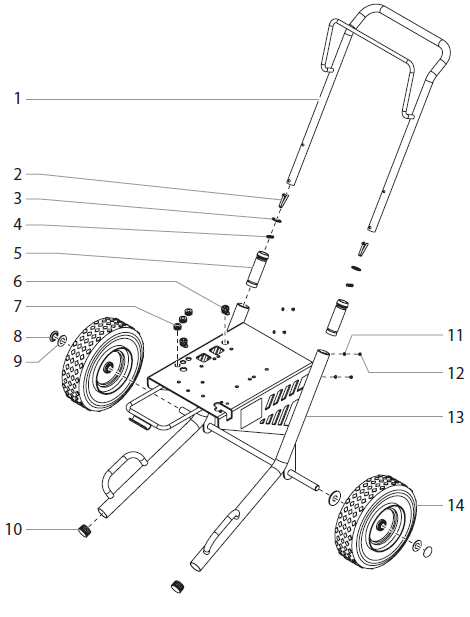

Advantage GPX 130 Cart Assembly Parts

Advantage GPX 130 Filter Assembly Parts

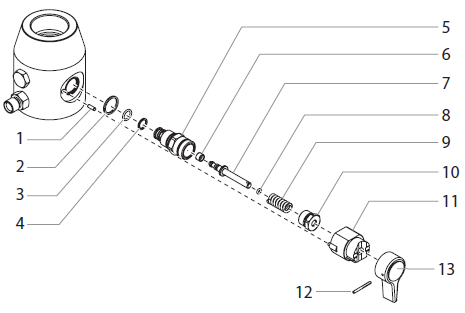

Advantage GPX 130 Prime Spray Valve Assembly Parts (P/N 0507690)

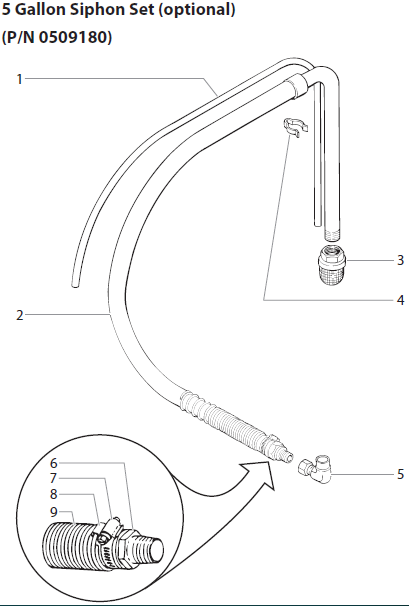

Advantage GPX 130 5 Gallon Siphon Set Parts

Advantage GPX 130 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - ADVANTAGE GPX 130 GAS PISTON PUMP

The Advantage GPX 130 Gas Piston Pump is a heavy-duty, high-output airless sprayer designed for professional contractors who demand consistent power, reliability, and superior performance on demanding job sites. Over time, continuous spraying causes wear on critical components, making regular maintenance essential to keep your sprayer running like new.

AllTitanParts provides a complete catalog of OEM replacement parts for the GPX 130, organized by clear sub-categories such as the Main Assembly, Drive Assembly, Fluid Section, Cart Assembly, Filter Assembly, Prime Spray Valve, 5-Gallon Siphon Set, and Accessories. Each part is engineered for perfect compatibility and long-term durability, ensuring smooth operation, optimal pressure control, and maximum productivity for every project.

Whether you're performing routine servicing or replacing worn components after heavy use, these genuine GPX 130 parts help maintain factory performance and extend the life of your gas piston pump sprayer.

Every part matches factory specifications for precise fit, guaranteed compatibility, and reliable long-term operation.

Includes all major assemblies—Main, Drive, Fluid, Cart, Filter, Prime Spray Valve, Siphon Set, and general Accessories.

Manufactured from high-strength, corrosion-resistant materials capable of handling high pressures and rugged jobsite conditions.

Parts are designed for straightforward replacement, reducing downtime and maintenance cost.

Improves output pressure, spray consistency, priming efficiency, and overall functionality.

Regular replacement of high-wear components extends the lifespan of the GPX 130 sprayer.

Advantage GPX 130 replacement parts are essential for:

These replacement parts ensure the GPX 130 remains dependable for professional painters, contractors, and maintenance crews.

These are the most common wear items. Replace every 3–6 months depending on daily usage, type of coating (thicker coatings wear faster), maintenance habits. Signs you need replacement if pressure loss , pump not holding pressure and material leaking from throat

Replace or check drive parts if you notice slower pump cycling , increased vibration grinding or clicking noises and irregular pump strokes.Worn drive rods, bearings, and gears are common causes.

Filters Assembly should be cleaned daily, replaced every 1–2 months If using heavy or gritty coatings, replace more frequently.Dirty filters cause pressure fluctuations and excessive pump wear.

Common causes are worn or damaged Prime Spray Valve ,Air leaks in the siphon hose.Clogged inlet strainer and ball valve wear in the fluid section. Replacing the prime spray valve parts or siphon set usually solves the issue.

Replace if you notice cracks in the hose,air bubbles during suction, clogged or damaged inlet strainer and reduced material flow.Often, changing just the strainer or o-rings is enough unless the hose is damaged.