Subcategories

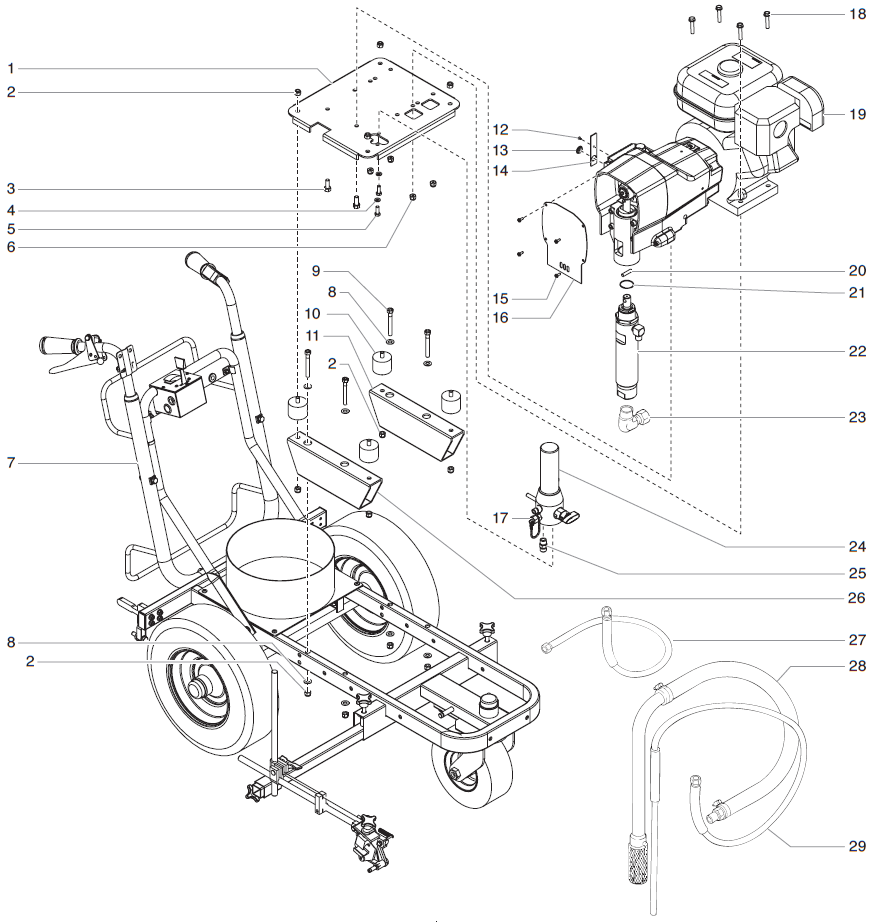

LineCrew 1600 Main Assembly

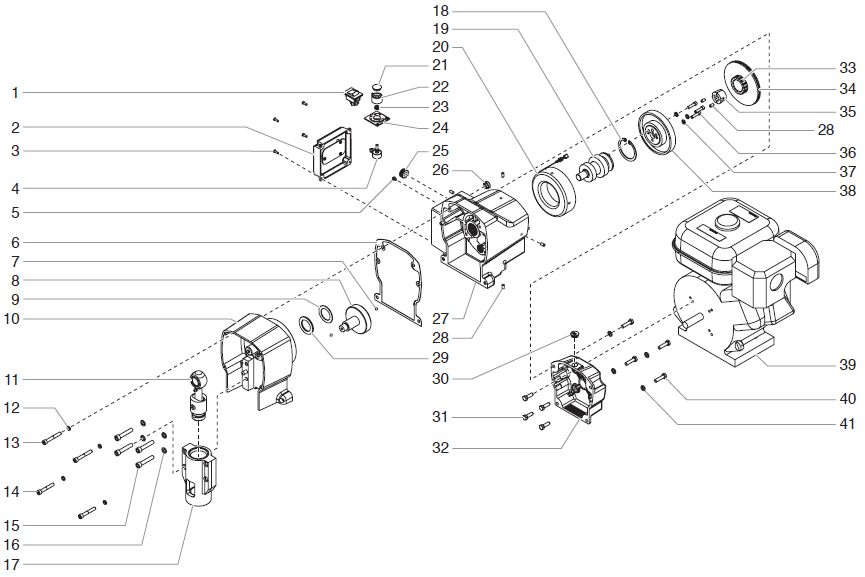

LineCrew 1600 Drive Assembly

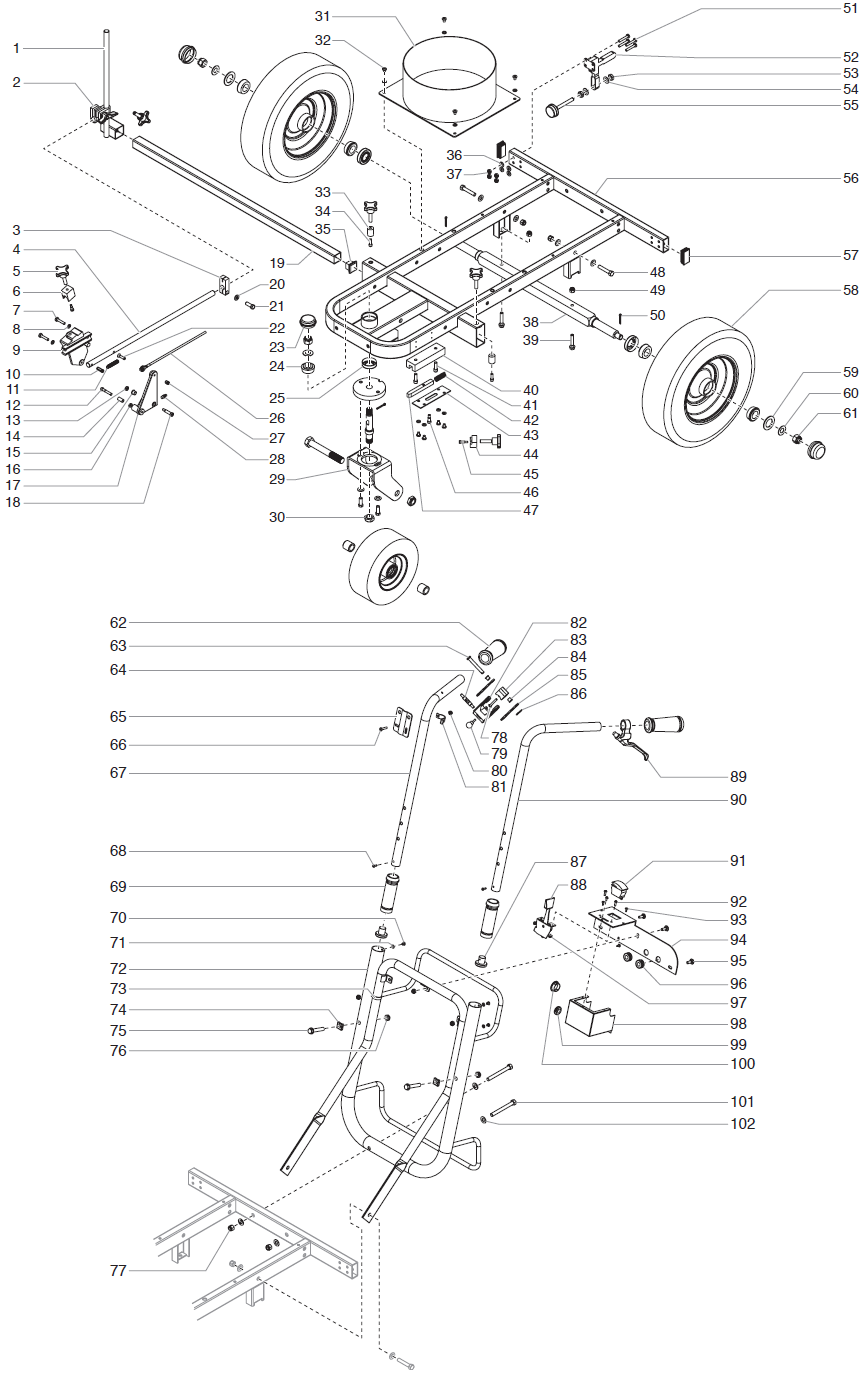

LineCrew 1600 Cart Assembly (P/N 0509161)

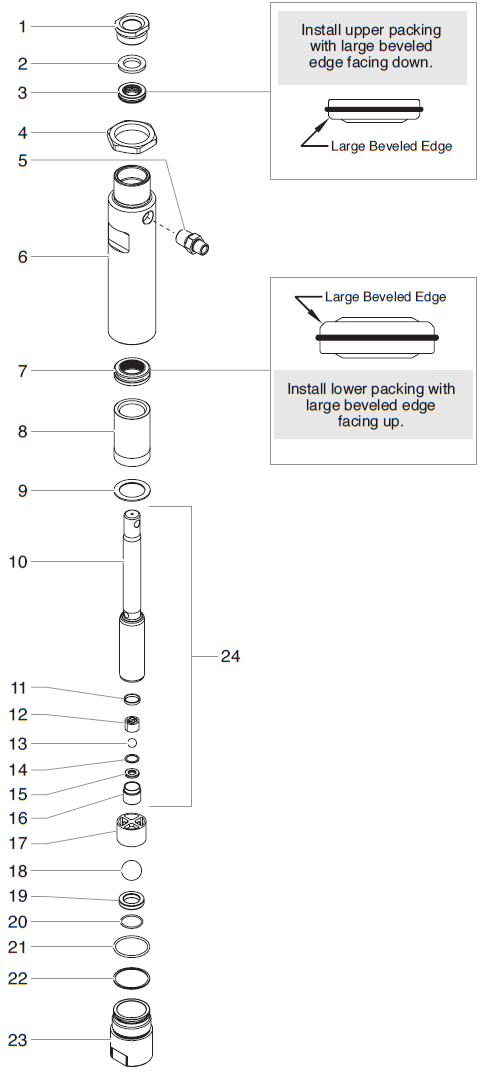

LineCrew 1600 Fluid Section Assembly (P/N 0509144)

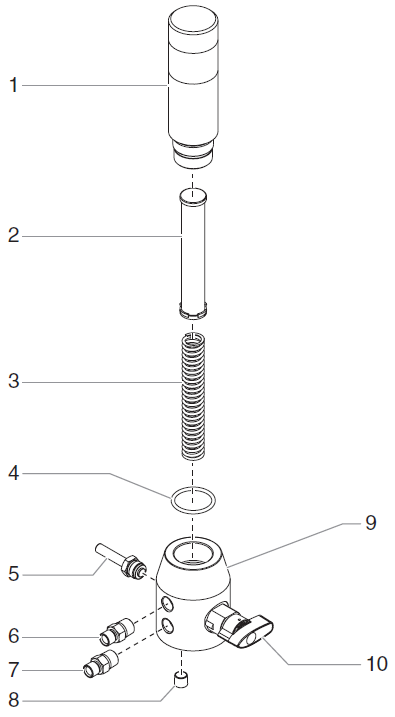

LineCrew 1600 Filter Assembly

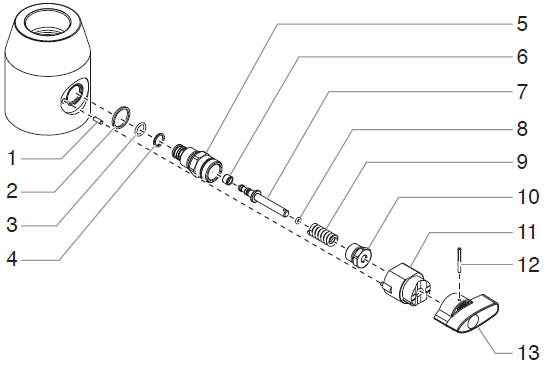

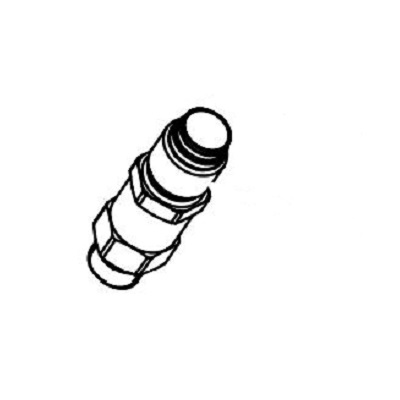

LineCrew 1600 PRIME/SPRAY Valve Assembly (P/N 0507690)

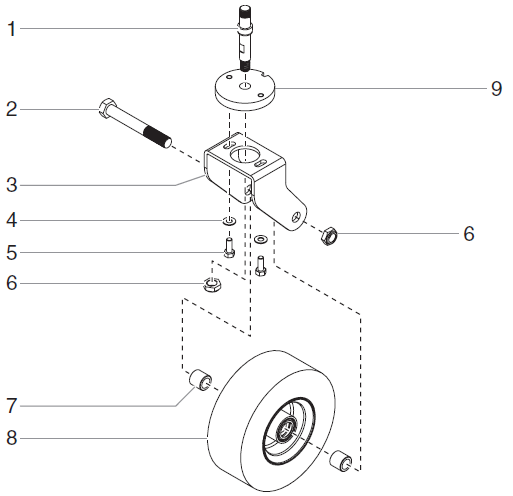

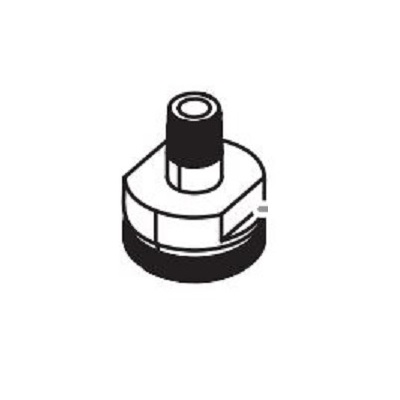

LineCrew 1600 Caster Assembly (P/N 0509250)

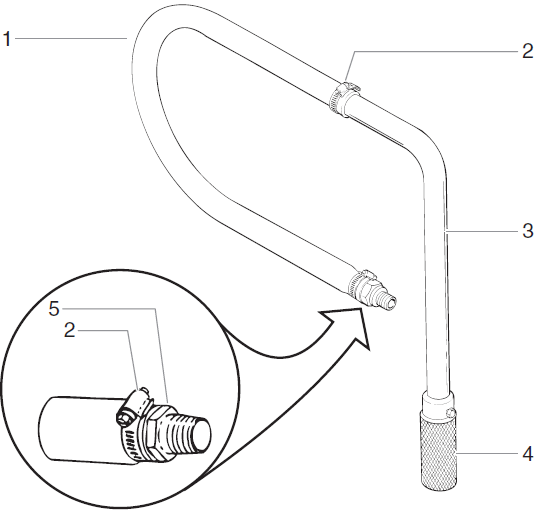

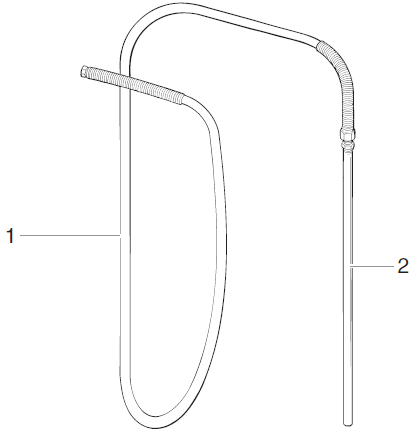

LineCrew 1600 Suction Hose Assembly (P/N 0509297)

LineCrew 1600 Return Hose Assembly (P/N 0509173)

NEW PRODUCTS FOR FEBRUARY - LINECREW 1600 LINE STRIPER

The LineCrew 1600 Line Striper is a rugged, high-output striping machine designed for contractors who demand power, precision, and reliability on every job. Built to handle demanding projects, it integrates essential performance components, including the LineCrew 1600 Filter Assembly, LineCrew 1600 PRIME/SPRAY Valve Assembly (P/N 0507690), LineCrew 1600 Caster Assembly (P/N 0509250), andLineCrew 1600 Suction Hose Assembly (P/N 0509297).

These assemblies work together to deliver smooth paint flow, easy priming, stable maneuverability, and efficient performance even during long workdays. Whether you’re striping highways, parking complexes, athletic fields, or industrial spaces, the LineCrew 1600 is engineered to stay consistent, dependable, and user-friendly. It’s built for professionals who want speed without sacrificing accuracy.

The LineCrew 1600 Line Striper is the ideal choice for contractors working on high-volume, large-scale striping projects.

The LineCrew 1600 Filter Assembly removes debris and paint impurities to prevent clogs. If you notice pulsation or weak spray output, the filter may need cleaning or replacement.

If priming becomes difficult or switching between modes feels stiff, the PRIME/SPRAY Valve Assembly may have internal wear or paint buildup. Servicing or replacing the valve restores smooth operation.

Difficulty steering, wobbling, or uneven rolling often indicates wear in the Caster Assembly. Replacing the caster ensures stable movement and straight-line accuracy.

A cracked or clogged Suction Hose Assembly can lead to priming failures, air leaks, and inconsistent paint flow. Replacing it ensures strong suction and steady spray performance.

Regular cleaning of the Filter Assembly, checking the Suction Hose Assembly, lubricating moving parts like the Caster Assembly, and servicing the PRIME/SPRAY Valve Assembly help keep the machine operating smoothly and extend its lifespan.