Buy CS5100 Spray System Parts & Accessories Online

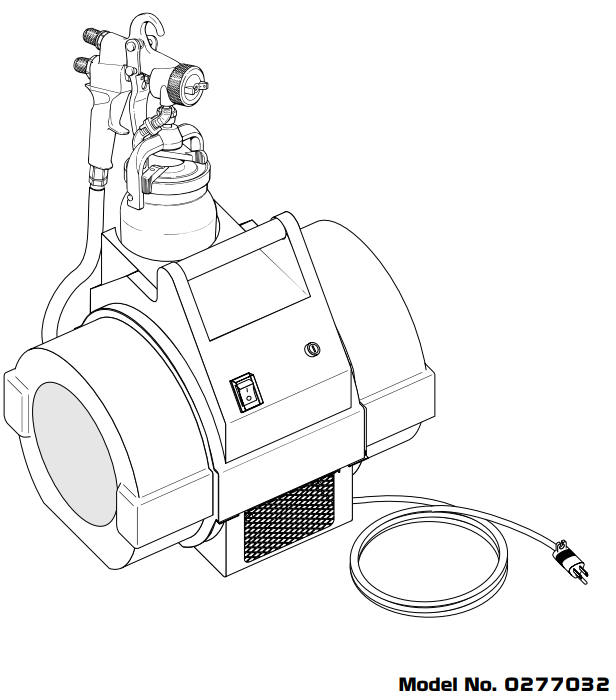

The Titan CS5100 is a portable HVLP (High-Volume Low-Pressure) spray system designed for fine finishing tasks. It uses a turbine to supply a large volume of air at low pressure, atomizing paint or coating material for smooth, even coverage. The system includes components such as a power switch, power cord, fuse, dual-air filters (for atomizing and cooling air), a cup holder, an air hose, and an air outlet, giving users a ready-to-use spray setup once assembled.

Key Features

- HVLP turbine-driven air supply: High volume of air at low pressure, ideal for fine finishing with minimal overspray and bounce-back.

- Dual-filtration system: Separate filters for atomizing air and cooling air. This ensures clean, moisture-free atomizing air and protects the turbine from debris.

- Adjustable spray control: The user can adjust spray fan size, spray pattern (round, horizontal, vertical), and fluid/air mixture via knobs on the spray gun, enabling precise control over finish.

- Portable and plug-and-spray ready: Comes with power cord, hose, cup holder designed to plug into standard power and start spraying without complex setup.

- High transfer efficiency: Because of HVLP design, material waste is reduced, and more paint actually adheres to the surface, making jobs more economical and environmentally compliant.

Applications

The CS5100 is best suited for fine finishing and detail work rather than large-scale industrial spray jobs. Typical uses include:

- Furniture, cabinets, and woodwork

- Interior doors, frames, moldings, trims

- Metalwork gates, railings, appliances, fixtures

- Doors frames, window frames, lockers, shutters

- Small- to medium-scale projects requiring precise, controlled coating

- Multi-color or decorative finishes where overspray must be minimized

Because of its HVLP characteristics, it’s especially good where controlled application, smooth finish, and reduced overspray are priorities, e.g., cabinetry, trim work, furniture, and fixtures.

FAQs

1. How often should I clean or replace the filters?

You should clean the filters after each painting session by tapping them, blowing them out with air, or rinsing (if compatible), then let them dry fully before reinstalling. Over time, filters degrade or clog; once cleaning no longer restores airflow, replace them.

2. What type of power supply and grounding is required?

The CS5100 must be plugged into a properly grounded 3-slot outlet. If a grounded outlet isn’t available, only a temporary adapter may be used, but it must be properly grounded with a metal screw to a permanent ground, and it is only a short-term solution until a proper outlet is installed by an electrician.

3. Can I use any solvents to clean the spray system?

No, avoid highly flammable or halogenated solvents (e.g., lacquer thinner) for cleaning. They are incompatible with the turbine and internal components and may cause fire or damage.

4. What if I get restricted or no airflow from the turbine?

Common causes of airflow issues include the spray gun’s air-flow knob being turned off, clogged air filters, a blown fuse, insufficient power supply, or worn turbine brushes. In some cases, restricted airflow can also come from a damaged or improperly connected Titan 0275276 Hose Assembly 6.0 m.

5. How do I maintain the spray gun, hose, and nozzle for best results?

After each use, flush the gun, hose, and nozzle thoroughly with appropriate cleaning fluid (compatible with the painted material), then dry completely. Clean or replace hose seals, O-rings, foot pad, and nozzle components regularly and inspect for wear or clogging before each use. This helps prevent poor atomization, uneven spray, or damage.