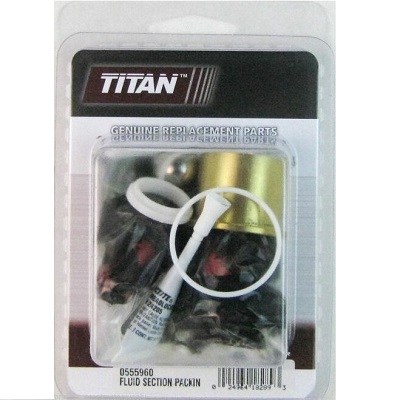

Part 0555960 is a repacking kit containing the seals and packings needed to prevent fluid leaks from the pump assembly. It restores the pressure integrity of the fluid section and is essential for routine maintenance on compatible sprayer models.

| Part Number | 0555960 |

|---|---|

| Part Description | Repacking Kit |

| Fits | Advantage GPX 85; PowrLiner 2850 GB_D_F; PowrLiner 1800M, 2800M; SprayTech GPX 85 |

| Condition | New |

The 0555960 repacking kit includes a complete set of seals, packings, and gaskets designed to reseal the high-pressure pump section. These components prevent fluid from leaking around the plungers and between the static joints of the fluid block.

Worn packings lead to fluid loss, pressure drops, contamination of the crankcase oil, and reduced spraying performance. Using this kit to perform a repack is a standard maintenance procedure that restores pump efficiency and prevents more serious internal damage.

| Dynamic Sealing | Provides new seals that contain fluid around the reciprocating plungers |

|---|---|

| Static Sealing | Includes gaskets to seal joints between the fluid block and manifold |

| System Integrity | Restores the pump's ability to build and maintain full operating pressure |

| Visible Pump Leaks | Fluid dripping or weeping from the packing area around the plunger rods |

|---|---|

| Pressure Loss | Inability to reach or maintain the sprayer's normal operating pressure |

| Oil Contamination | Paint or solvent thinning the crankcase oil, indicating seal failure |

| Preventive Maintenance | Scheduled service interval to avoid unexpected failures during use |

Part 0555960 is designed for the pump assemblies used in the following sprayer models. It contains the correct size and quantity of seals for these specific units.

| Sprayer Model | Component |

|---|---|

| Advantage GPX 85 | Repacking Kit |

| PowrLiner 2850 GB_D_F | Repacking Kit |

| PowrLiner 1800M | Repacking Kit |

| PowrLiner 2800M | Repacking Kit |

| SprayTech GPX 85 | Repacking Kit |

A pump repack is often part of a broader fluid section service. These components are frequently inspected or replaced at the same time to ensure complete system reliability.

Worn inlet and outlet valves are a common cause of pressure loss and are often replaced during pump service.

Inspect plungers for scoring or wear; damaged plungers will quickly ruin new packings.

Change the oil and filter if it has been contaminated by fluid leaking past the old packings.