Part #: 316-505

Part #: 0293169

Part #: 0293932

Part #: 9805251

Part #: 0293933

Part #: 759-293A

Part #: 0327226

Part #: 0293930

Part #: 858-003

Part #: 759-107

Part #: 0523561

Part #: 9805251

Part #: 0293929

Part #: 0293928

Part #: 0293926

Part #: 0293927

Part #: 0293966

Part #: 0293974

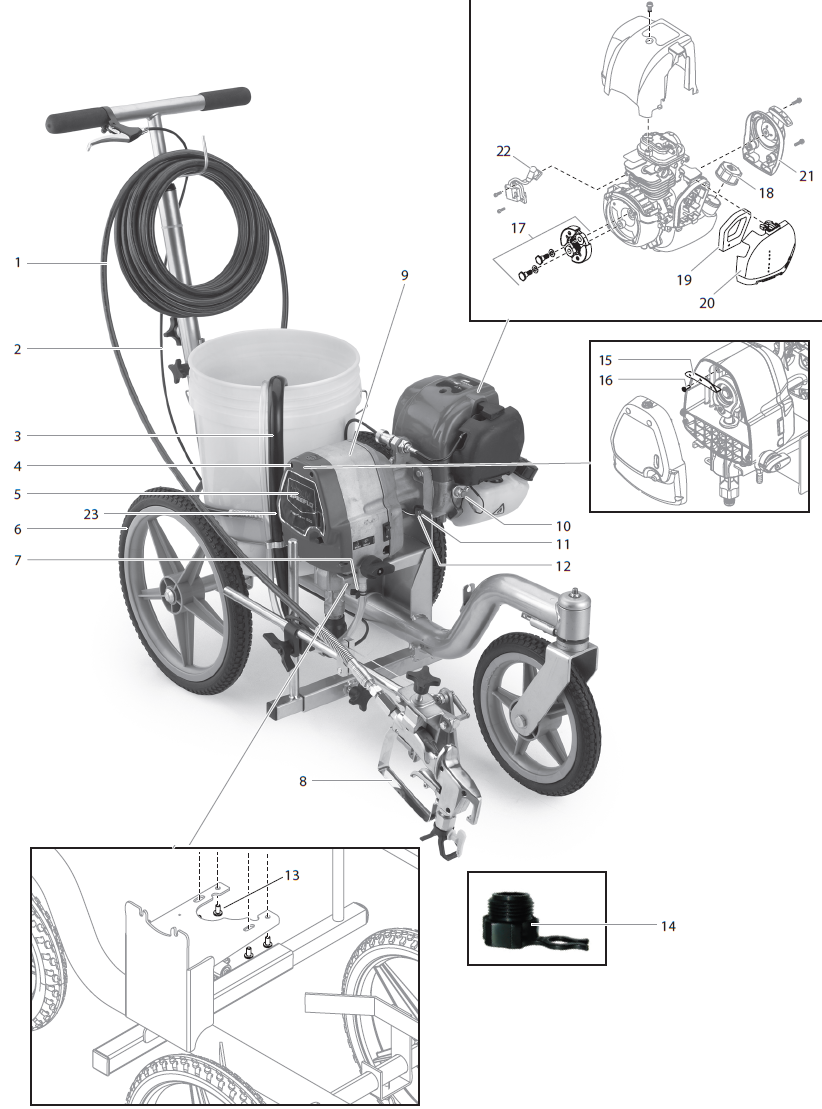

The PowrLiner 850 Main Assembly is the backbone of the Titan PowrLiner 850 line striping machine. Built for contractors, field managers, and maintenance crews, this assembly houses the essential components that keep your sprayer running smoothly and consistently. Whether you’re marking parking lots, roadways, or athletic fields, keeping the main assembly in top shape ensures dependable performance on every project.

The main assembly contains several critical parts that work together to maintain the durability and efficiency of your sprayer. Within this section you’ll find:

This main assembly is specifically designed for the Titan PowrLiner 850, a compact yet powerful striping machine. The 850 is commonly used for:

By replacing or maintaining the parts within the main assembly, you ensure the sprayer continues delivering high-quality, professional results on every surface.

Line striping machines work in tough environments—dust, uneven surfaces, and constant use can cause wear. By inspecting and replacing parts like the recoil, suction set, wheels, and hoses, you extend the lifespan of your machine and prevent costly downtime. The PowrLiner 850’s modular assembly design also makes it easy to identify and order the correct parts when needed.

At AllTitanParts, we make it simple to find and purchase the exact replacement parts you need. From the Titan Ruitao Recoil to the Titan Spray Hose, our site offers detailed breakdowns and diagrams to ensure you order the right component the first time. Every part is designed to meet Titan’s standards for durability and performance, giving you confidence in every repair or rebuild.

Whether you’re replacing the PowrLiner 850 Main Assembly entirely or just need a single component like the Titan Suction Set Assembly, you’ll find everything at AllTitanParts.com. Browse today and keep your equipment performing at its best.

Typical warning signs include paint leaks around the fluid section, pressure fluctuations, difficulty priming, inconsistent spray patterns, or reduced engine responsiveness. These issues often indicate wear in components such as the fluid section packing, piston rod, inlet valve, or prime spray valve assembly.

The fluid section repacking kit should be replaced when you notice paint leaking, loss of pressure, or uneven spray output. For contractors with frequent use, repacking may be required after extended operating hours or at the first signs of reduced pump efficiency to prevent further internal damage.

A worn or damaged piston rod can lead to inconsistent pressure, poor paint atomization, and premature wear of packings and seals. Replacing the piston rod restores smooth pump movement and helps maintain steady, professional-quality striping results.

Loss of prime is commonly caused by a failing inlet valve assembly, worn packings, or air leaks in the fluid section. Inspecting and replacing the inlet valve assembly ensures proper paint intake and reliable pump priming during operation.

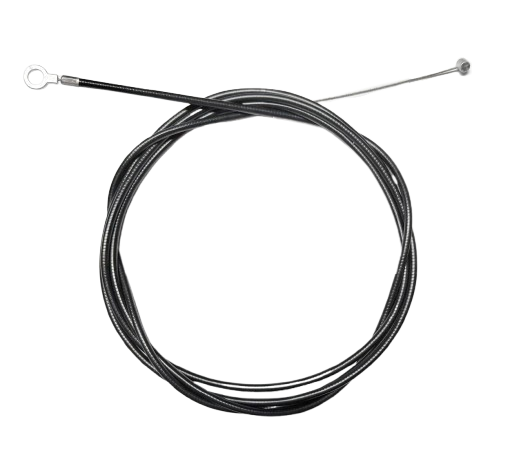

The prime spray valve assembly should be serviced if it becomes hard to switch modes, leaks, or does not fully engage. The throttle cable assembly should be replaced if engine speed control feels stiff, delayed, or inconsistent, as proper throttle cable response is essential for smooth operation and accurate line striping.