Subcategories

LCX 130 Main Assembly

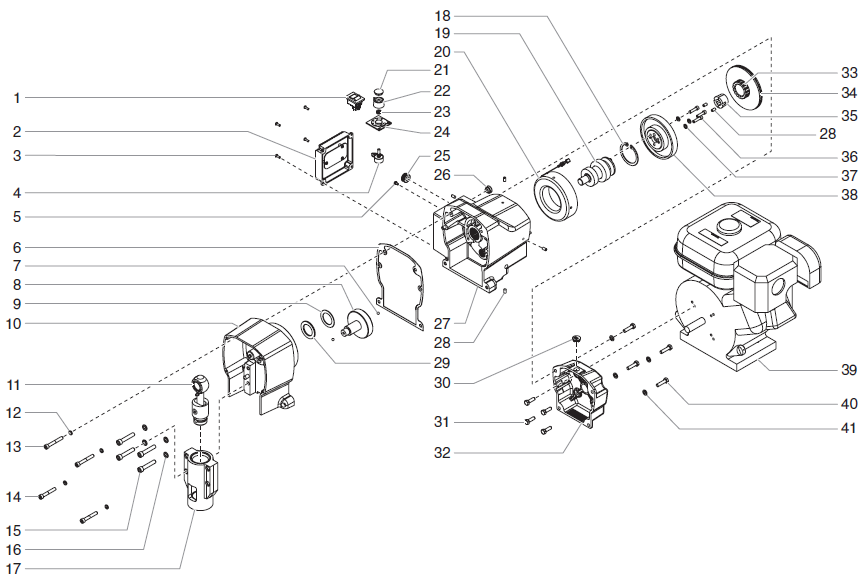

LCX 130 Drive Assembly

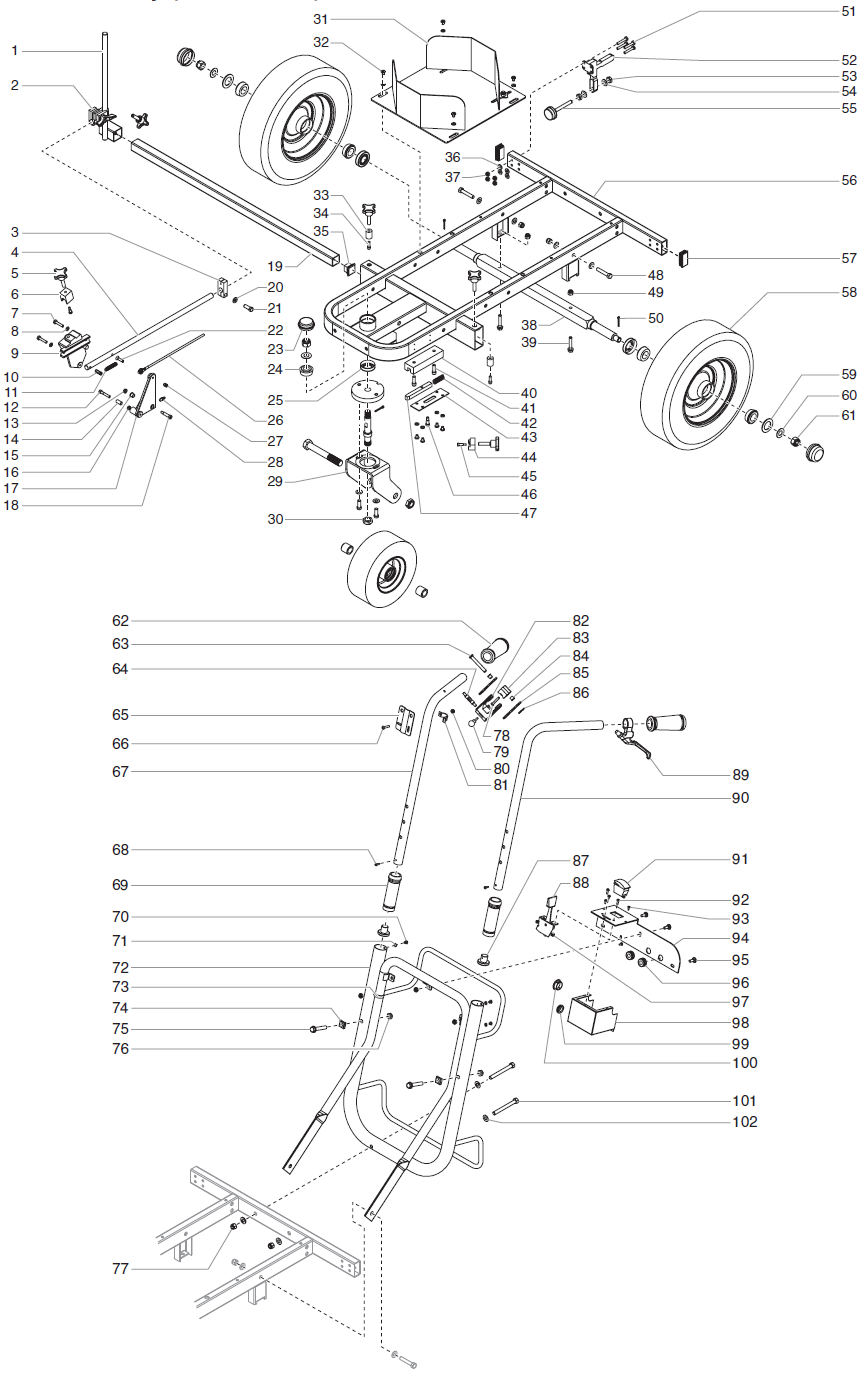

LCX 130 Cart Assembly (P/N 0509161)

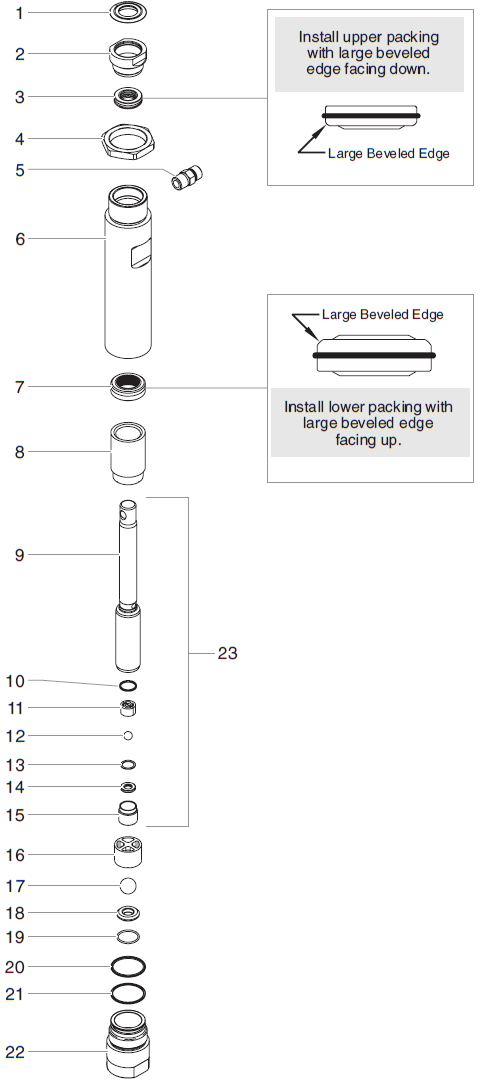

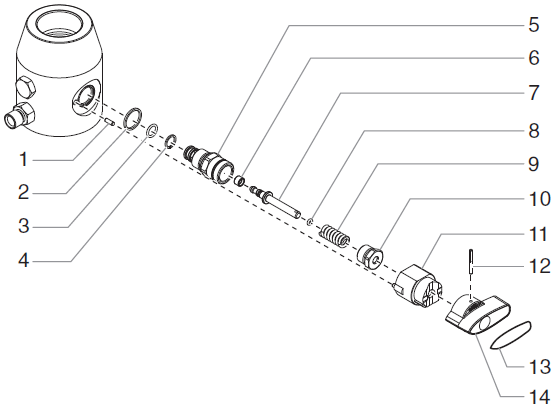

LCX 130 Fluid Section Assembly (P/N 0509133)

LCX 130 Filter Assembly

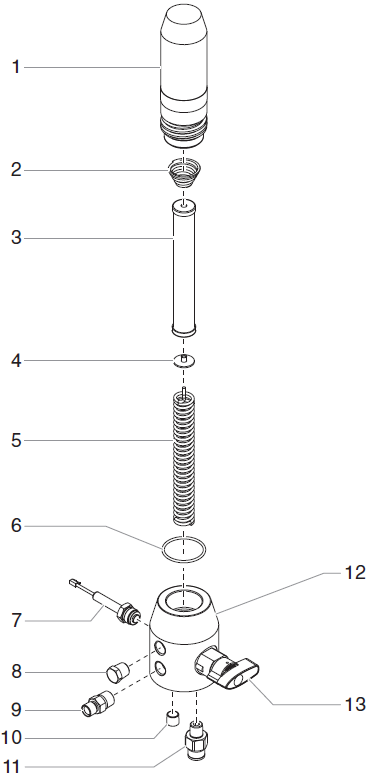

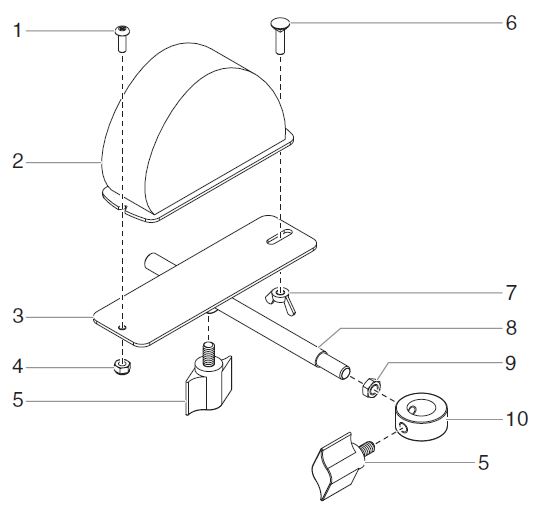

LCX 130 PRIME/SPRAY Valve Assembly (P/N 0507690)

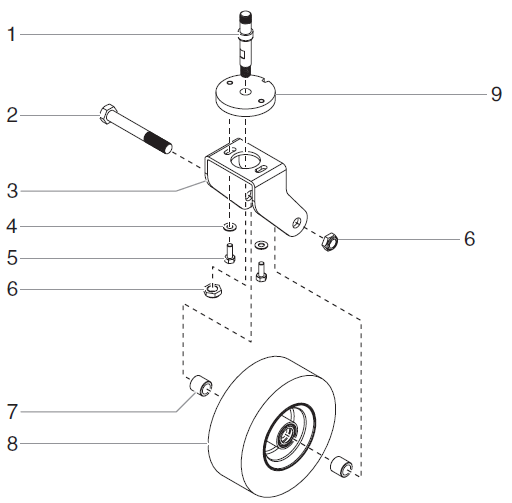

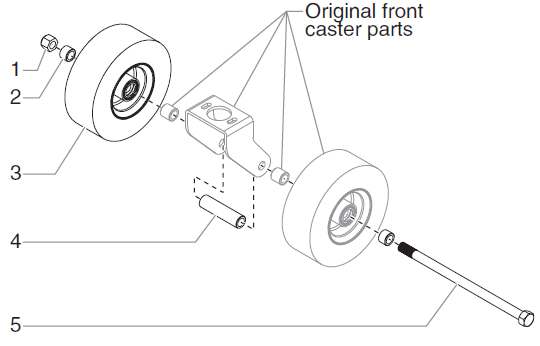

LCX 130 Caster Assembly (P/N 0509250)

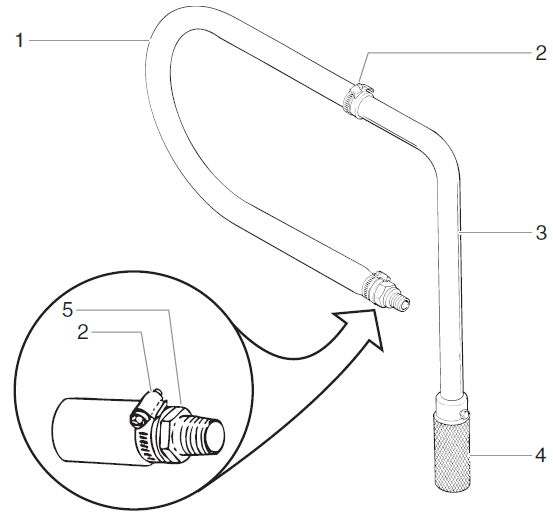

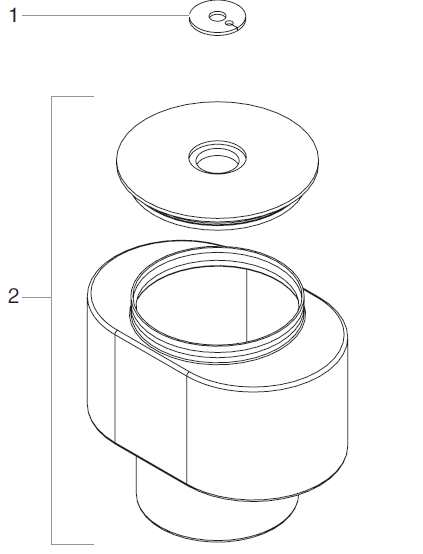

LCX 130 Siphon Set (P/N 0509297)

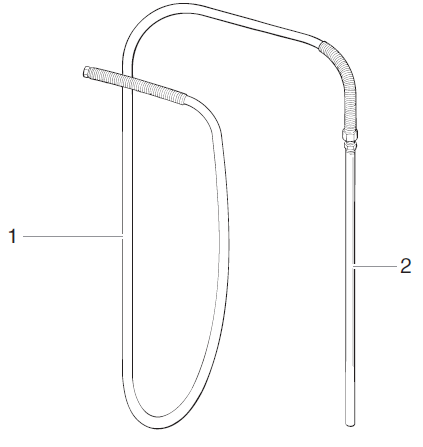

LCX 130 Return Hose Assembly (P/N 0509173)

LCX 130 Accessories Turf Kit (P/N 0509965)

LCX 130 12 Gallon Paint Hopper (P/N 0509943)

LCX 130 Second Gun Kit (P/N 0509941)

LCX 130 Floating Gun Mount (P/N 0509942)

LCX 130 Line Laser (P/N 0509944)

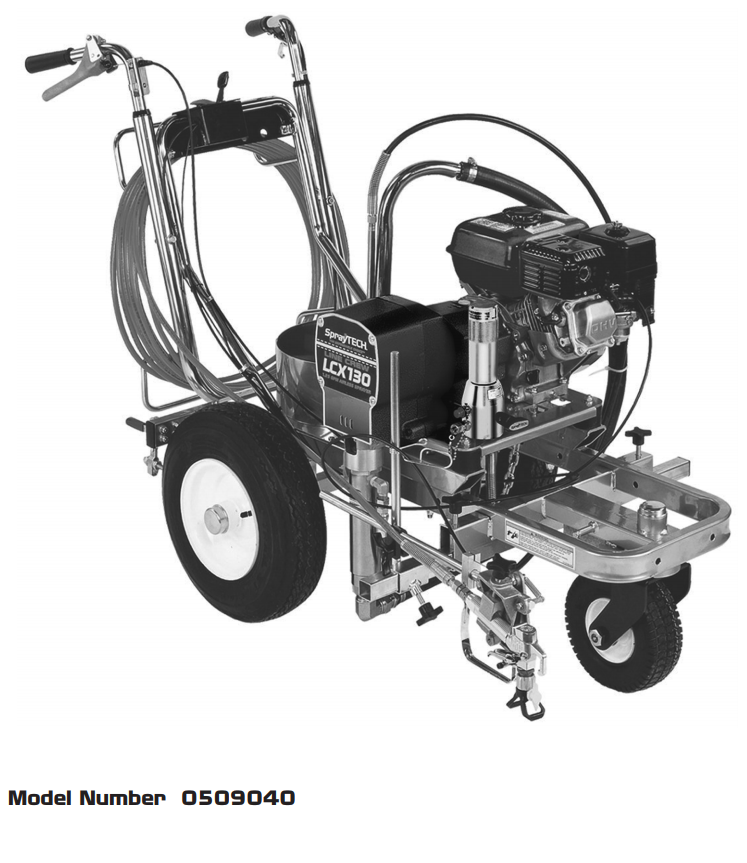

NEW PRODUCTS FOR FEBRUARY - LCX 130 LINE STRIPER

The LCX 130 Line Striper is designed for contractors who need reliable, consistent, and professional-quality striping performance on every project. Built for durability and precision, it’s engineered with high-quality components such as the LCX 130 Main Assembly, LCX 130 Drive Assembly, LCX 130 Fluid Section Assembly, and LCX 130 PRIME/SPRAY Valve Assembly, ensuring smooth operation from priming to finish.

Its rugged design, paired with components like the LCX 130 Cart Assembly, LCX 130 Caster Assembly, and LCX 130 Siphon Set, makes it easy to maneuver, maintain, and operate. Whether you're striping parking lots, sports courts, or commercial properties, the LCX 130 Line Striper delivers dependable results with minimal downtime.

The LCX 130 Line Striper is ideal for contractors, maintenance teams, and property managers who need a dependable, easy-to-use line-stripping solution.

The LCX 130 Main Assembly houses essential structural and operational components. If the machine feels unstable or vibrates excessively, the Main Assembly may need inspection or tightening.

The LCX 130 Drive Assembly is responsible for pushing power and stable movement. Worn drive parts can cause uneven rolling or difficulty maintaining straight lines, so regular checks are recommended.

If you experience pressure drops, inconsistent paint flow, or pulsation, the Fluid Section Assembly may have worn packings or clogged valves. Rebuilding or replacing this assembly restores smooth operation.

If switching between prime and spray becomes difficult, or the machine fails to prime properly, the PRIME/SPRAY Valve Assembly may have internal wear or debris buildup.

Air bubbles, poor suction, or frequent priming failures often point to cracks, clogs, or worn seals in the LCX 130 Siphon Set. Replacing it ensures steady paint delivery.

If you'd like, I can create product content for the LCX 1600, LineCrew, ProMark, or any other model in the same high-quality format.