Buy CS9100 Spray System Parts & Accessories Online

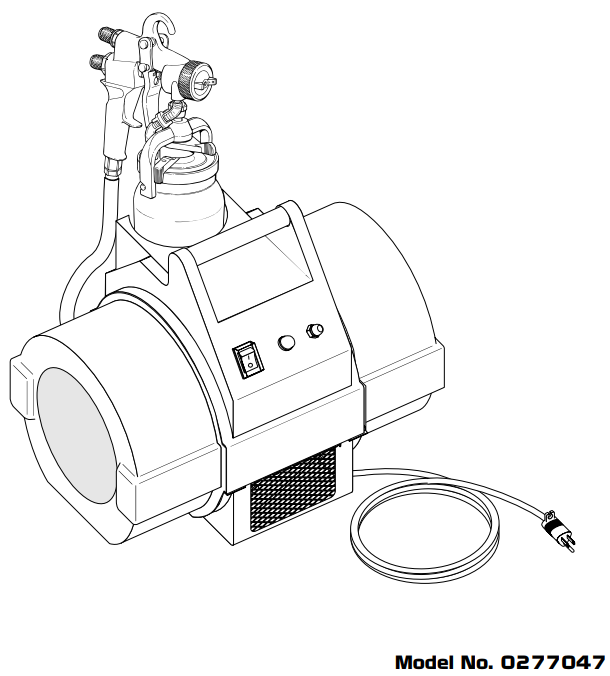

The CS9100 Spray System is a high-volume, low-pressure (HVLP) turbine-based spray system designed for applying coatings faster and more evenly than brushing or rolling — especially on surfaces where airless sprayers are too large or impractical It includes a turbine (air source), air hose, and spray gun (often a “Maxum II” HVLP gun), delivering atomized material via low-pressure high-volume air flow.

Key Features

- Four-stage turbine producing ~8–8.5 PSI This gives CS9100 enough power to spray heavier coatings with less thinning.

- Dual air-filtration system. There are two separate filters: one for atomizing air (fine mesh) and one for cooling air (coarse mesh), helping to ensure paint quality and protect the turbine.

- Filter-warning light + easy filter maintenance: A warning light alerts when airflow is restricted, signalling that filters need to be cleaned or replaced. Filters can be tapped out, blown with compressed air, or soaked (depending on material) and reused.

- Included HVLP spray gun(s) with “Maxum II” guns. Known for good atomization, high transfer efficiency (up to ~90%), and flexible adjustment of spray pattern, fan size, and material flow.

- Portability & user-friendly designDespite being a four-stage turbine, it’s relatively light (compared to competitive two-stage units), with a centered handle for balance, making it suitable for contractors needing mobility.

- Quiet operation. Thanks to a patented noise-reduction system, CS9100 tends to run more quietly than many airless or conventional sprayers.

- Ability to spray a wide range of coatings from stains, sealers, primers, lacquers, enamels, to latex (water-based) and multi-color or specialty coatings.

- Long hose-reach Supports up to about 60 feet maximum hose length (though it comes standard with ~30 ft hose), giving flexibility to work over larger areas without moving the turbine unit.

Typical Applications

The CS9100 is well-suited for fine finishing and medium-sized jobs rather than large-scale industrial coating. Typical use cases include:

- Furniture refinishing (wood furniture, cabinetry)

- Doors, window frames, and moldings (e.g. crown molding, door jambs)

- Cabinets, lockers, and interior woodwork

- Renovation and repainting jobs living spaces, public spaces, courtyards, etc.

- Coatings such as lacquers, sealers, primers, water-based and oil-based paints/enamels, stains, and multi-color coatings

FAQs

Q1: How often should I clean or replace the filters on the CS9100?

You should check the filter-warning light before each use. If the red warning light is on (or airflow seems reduced), remove the filters: tap them out, blow with compressed air, or soak in soapy water (or solvent if appropriate). Always let them dry completely before reinstalling. Over time, after multiple cleanings, filters may lose effectiveness and then should be replaced per the manufacturer’s parts list.

Q2: Can I spray thick or heavy coatings (e.g. enamels, heavier latex) without thinning them excessively?

Yes the four-stage turbine of CS9100 produces enough air pressure (circa 8–8.5 PSI) to atomize heavier coatings, which reduces the need for thinning for many materials.

Q3: What hoses and gun setup does CS9100 use, and how far can I spray from the turbine?

The system comes standard with a ~30 ft air hose, but supports up to about 60 ft hose length. It typically includes a “Maxum II” HVLP spray gun with a one-quart cup and #3 tip set. A second gun may also be included (or sold separately, depending onthe retailer).

Q4: What kind of maintenance does the turbine itself require?

Regular maintenance involves checking and cleaning/replacing filters to ensure proper airflow. Also, if there is restricted airflow or no airflow, check hose for blockages, check power supply, fuse, or turbine brushes. For turbine internal issues (e.g. worn brushes or a damaged commutator), service or replacement should be done at an authorized service center.

Q5: Is the CS9100 noisy? Can I use it indoors or in residential areas?

The CS9100 is designed with a patented noise-reduction system, and despite being a four-stage turbine, it runs as quietly as many competing two-stage units. That makes it more suitable for residential or indoor use compared to louder airless compressors.