Subcategories

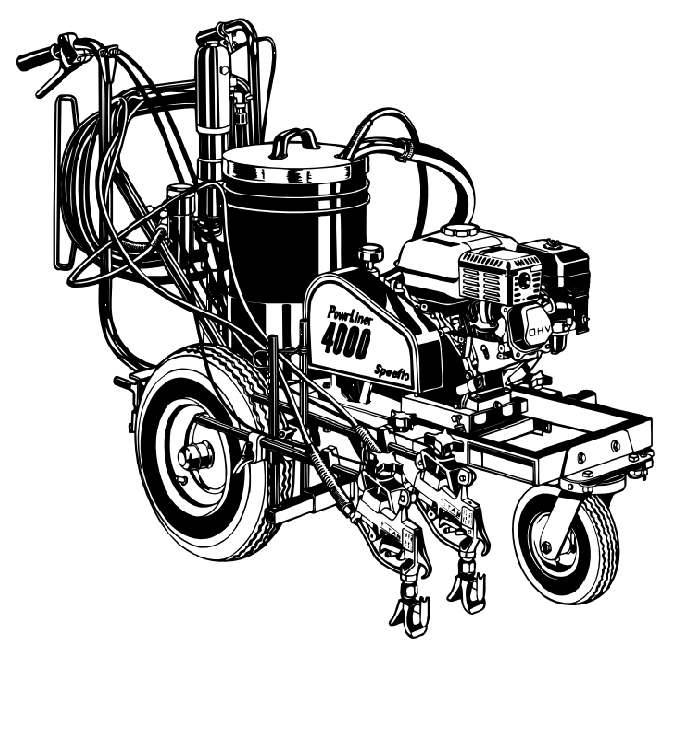

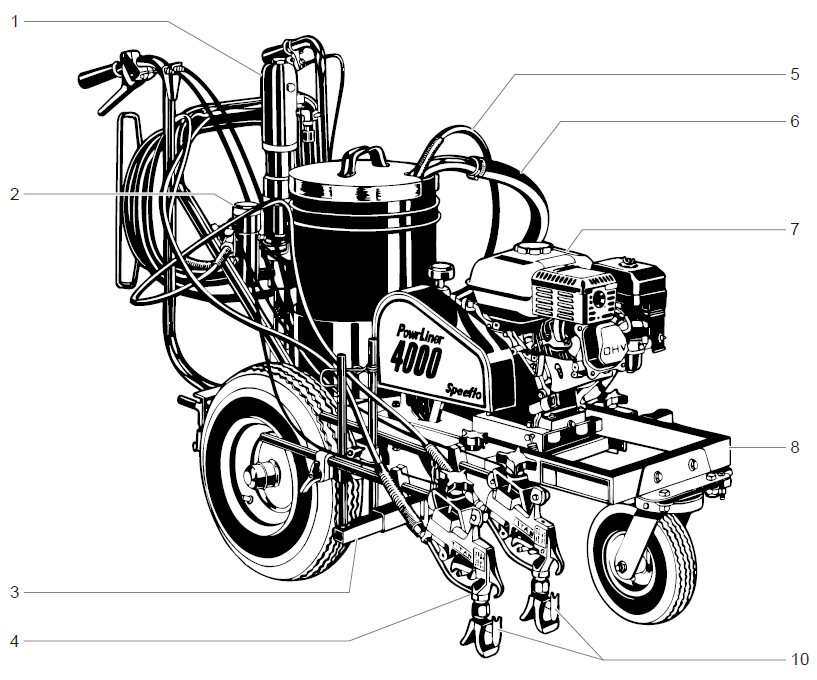

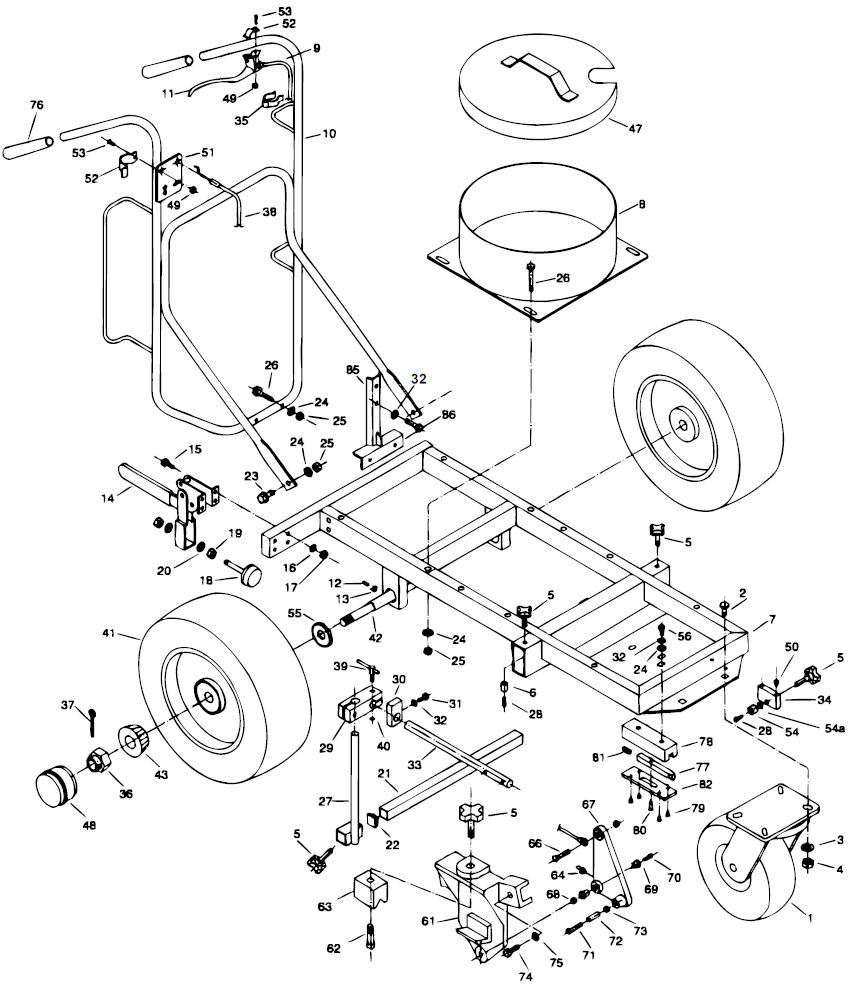

PowrLiner 4000 Main Assembly-Gas Model Parts

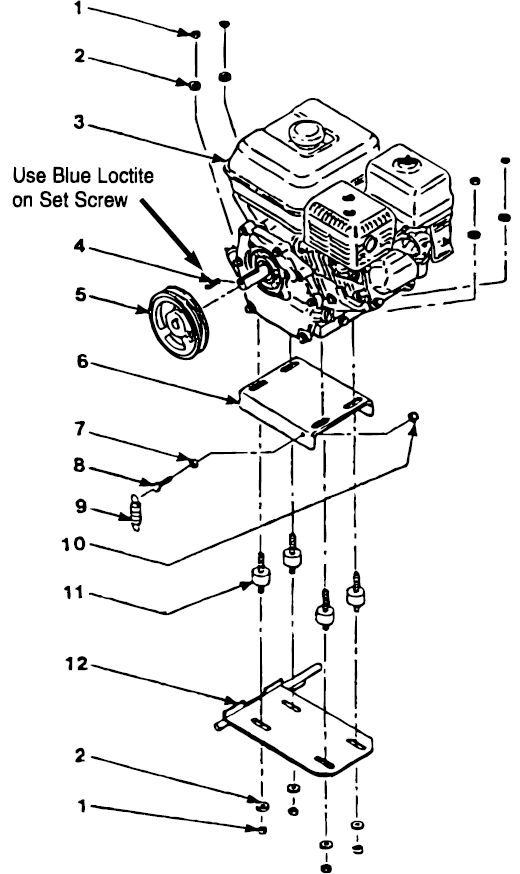

PowrLiner 4000 Gas Convertokits (P/N 506-105) Parts

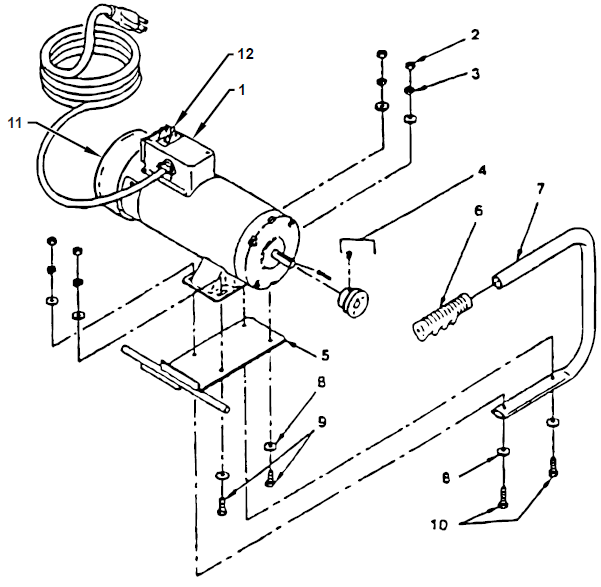

PowrLiner 4000 DC-Electric Convertokit Parts

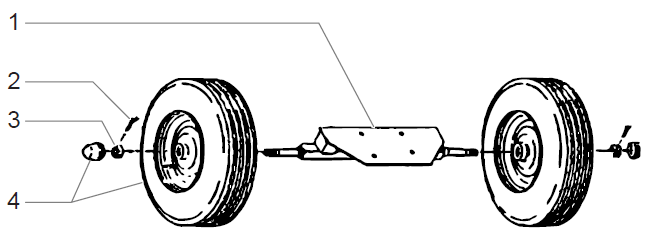

PowrLiner 4000 Cart Assembly(P/N 759-001) Parts

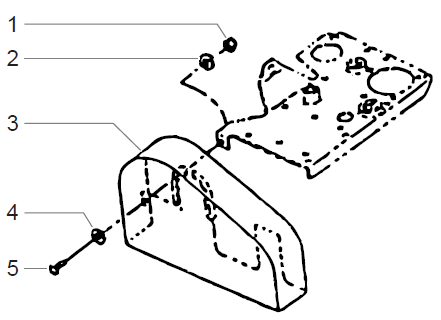

PowrLiner 4000 Belt Guard Assembly Parts

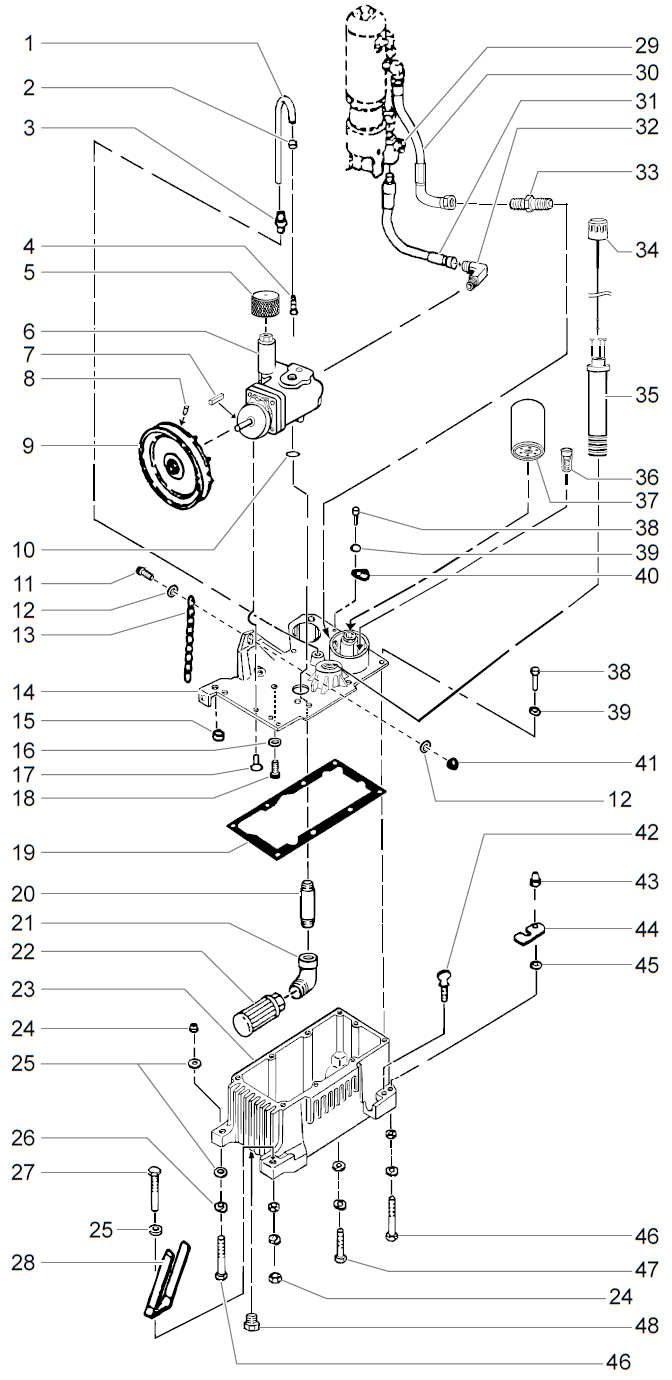

PowrLiner 4000 Hydraulic System Parts

PowrLiner 4000 Hydraulic Motor Parts

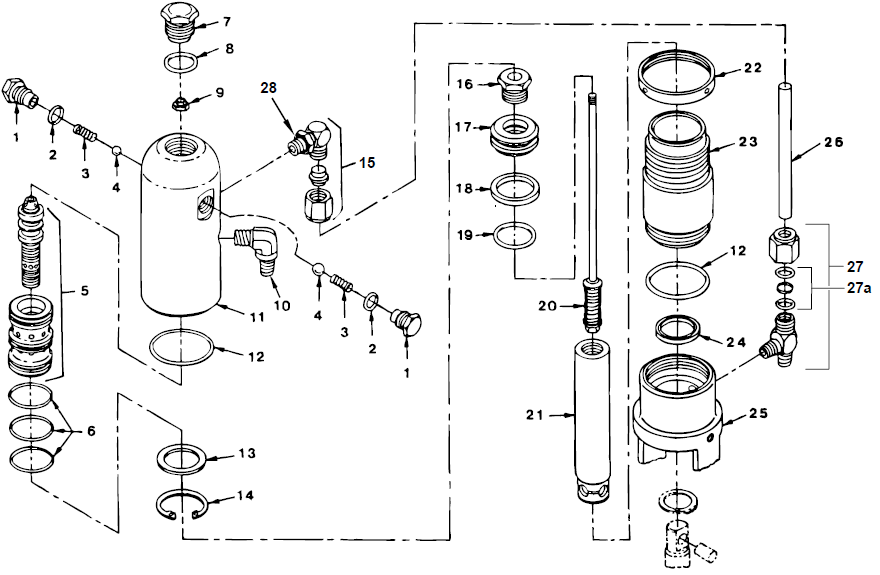

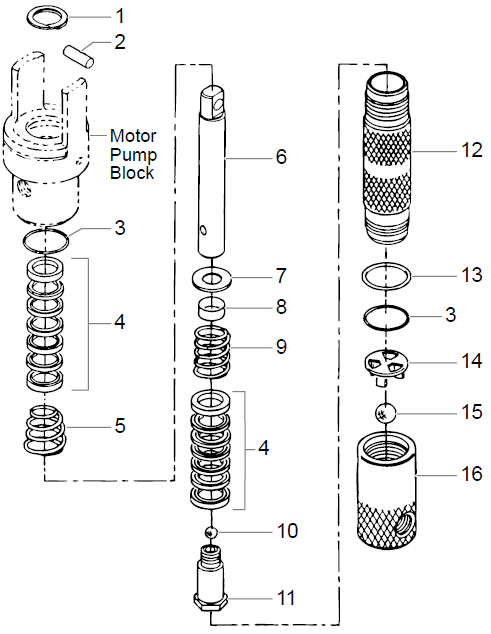

PowrLiner 4000 Fluid Pump Parts

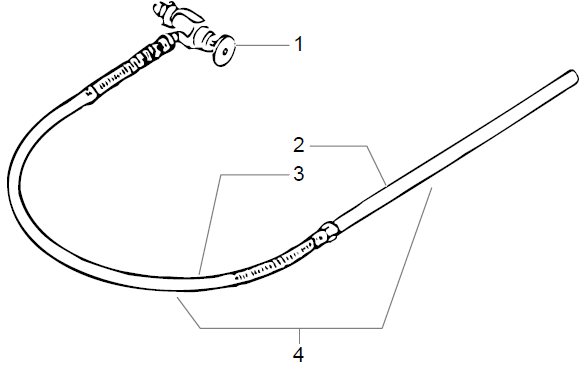

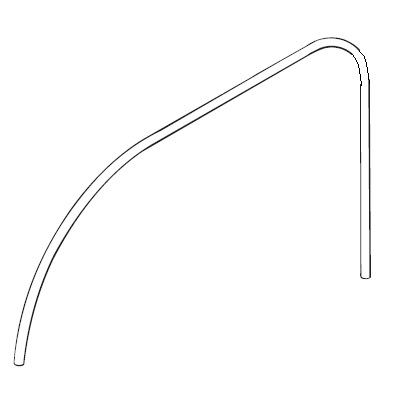

PowrLiner 4000 Bleed Line Assembly with Valve(P/N 840-212) Parts

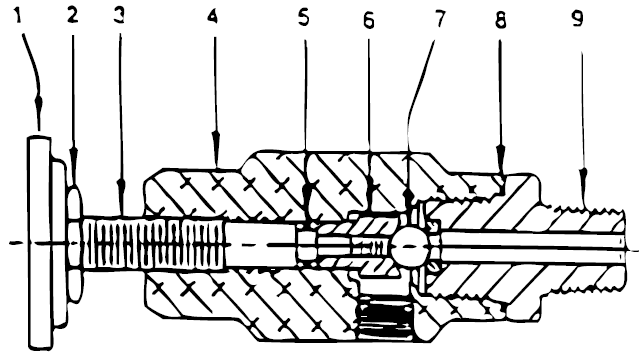

PowrLiner 4000 Bleed Valve Assembly(P/N 944-620) Parts

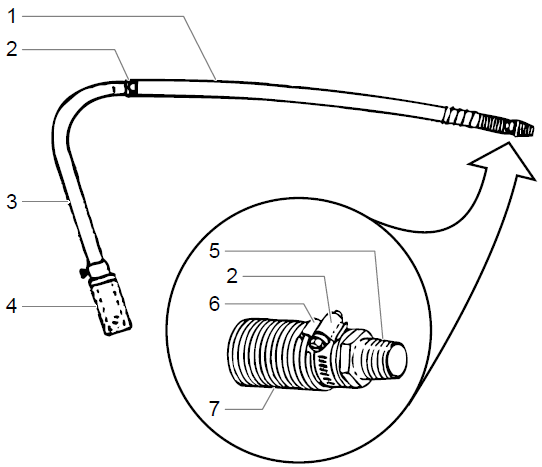

PowrLiner 4000 Siphon Hose Assembly Parts

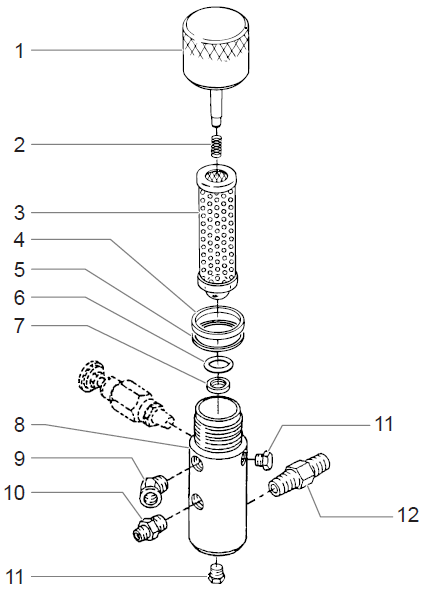

PowrLiner 4000 - 930 Outlet Manifold Filter Assembly with Check Valve Parts

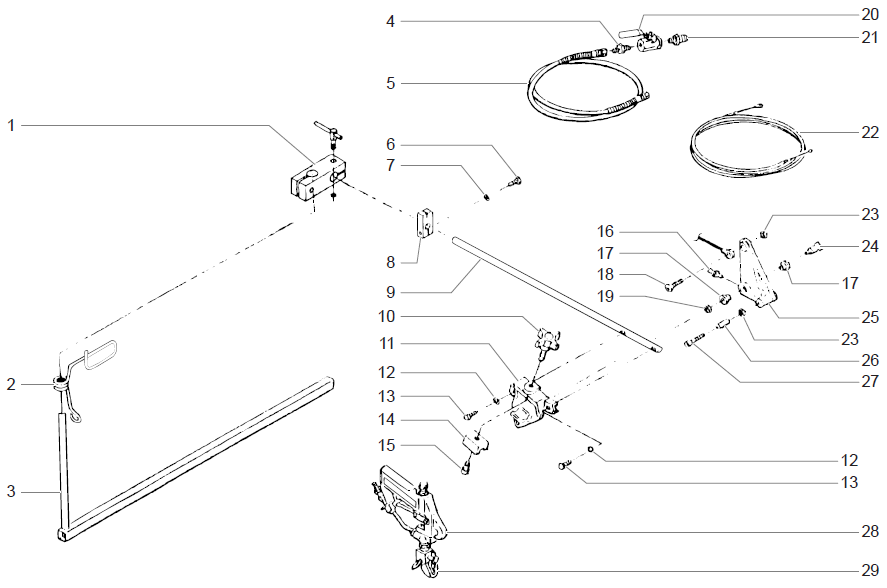

PowrLiner 4000 Second Gun Assembly Complete (P/N 759-055) Parts

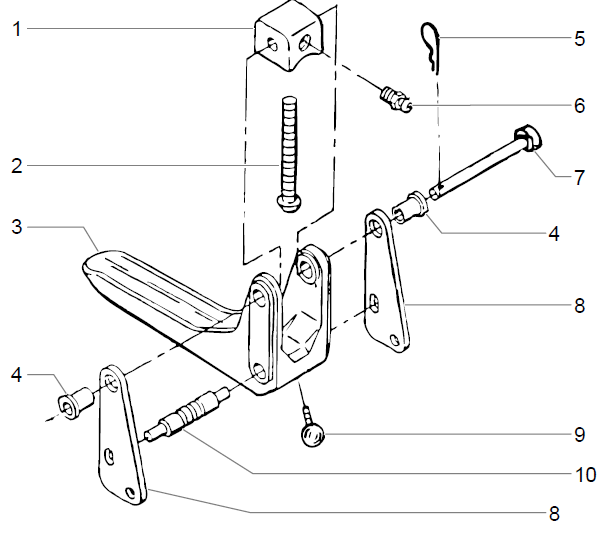

PowrLiner 4000 Trigger Assembly Parts

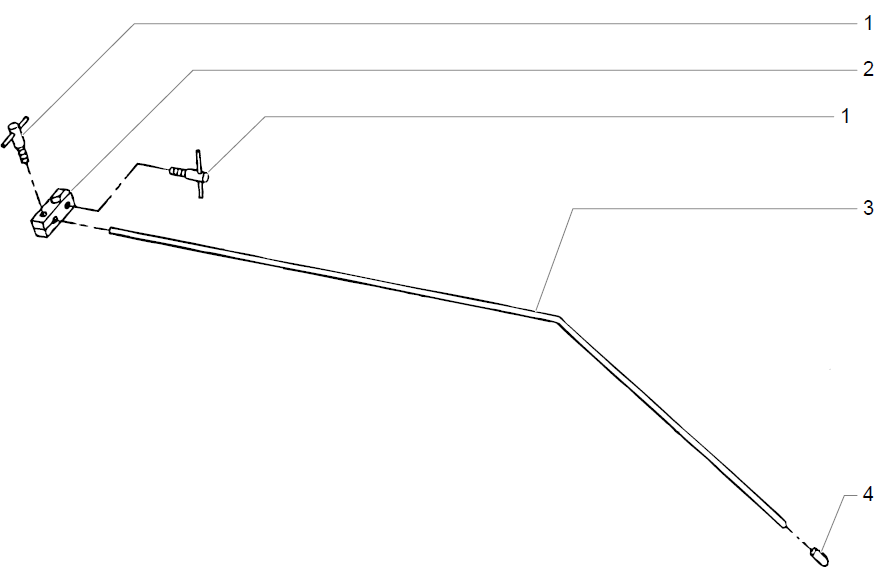

PowrLiner 4000 Line Pointer (P/N 424-620) Parts

PowrLiner 4000 Athletic Field Marking Kit/Turf Kit Parts

Powrliner 4000 Accessories Parts

NEW PRODUCTS FOR FEBRUARY - POWRLINER 4000 PARTS

The PowrLiner 4000 is a high-performance line striping machine engineered for professional contractors who demand power, precision, and reliability on every job. To keep this robust striping unit operating at peak performance, genuine PowrLiner 4000 Parts are essential.

At AllTitanParts.com, you’ll find every OEM replacement component needed to maintain or rebuild your sprayer, from pump parts and valve assemblies to filters, cart components, hoses, and accessories.

Each part is manufactured to exact Titan specifications, ensuring smooth paint flow, consistent pressure, and long-lasting durability for demanding striping applications.

If you experience pressure fluctuations, poor line quality, difficulty priming, or unusual noises, the pump seals, packings, or valves may be worn and require replacement.

Clean the filter of the 4000 filter pump after each major job. Replace it if you notice persistent clogging, reduced spray output, or pressure drops.

Common causes include worn inlet/outlet valves, blocked filters, air leaks in the siphon hose, or pump wear. Inspect these components and replace damaged parts as needed.

Yes, as long as you use compatible tips and maintain clean filters. For heavier coatings, ensure the pump and valves are in good condition to support proper flow.

Replace wheels, tires, fasteners, or bent frame parts when you notice vibration, uneven movement, or instability during striping. Proper cart maintenance ensures consistent line accuracy.