Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRBEAST 9700 (GAS)

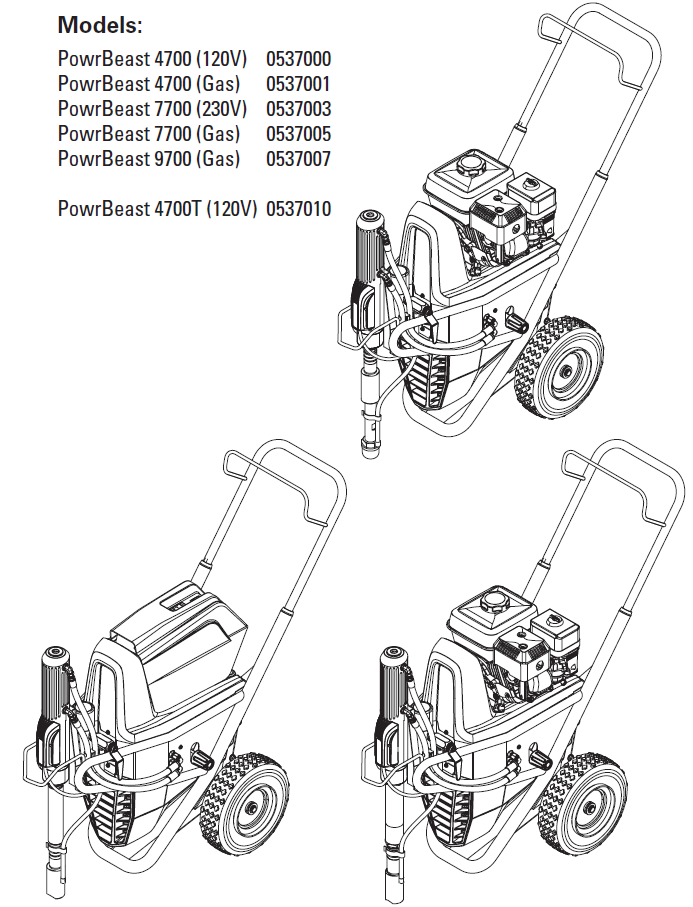

The PowrBeast 9700 (Gas) is one of Titan’s most powerful and heavy-duty hydraulic airless sprayers, engineered for large-scale industrial, commercial, and professional contractor jobs. Built with Titan’s advanced hydraulic system and oversized fluid section, the 9700 Gas delivers maximum durability, superior pressure consistency, and the capability to spray the thickest coatings with ease.

Whether you’re applying elastomerics, block fillers, fireproofing materials, heavy primers, or high-volume architectural coatings, the PowrBeast 9700 performs with exceptional reliability.

At AllTitanParts, you can easily find every replaceable assembly for the PowrBeast 9700 Gas including the Fluid Section II, Hydraulic Motor, High-Pressure Filter (0537220A), Bleed Valve Assembly, Solenoid Assembly, and Accessories Parts to keep your sprayer working at peak performance.

Pressure loss usually points to worn packings or piston components inside the Fluid Section II. When the piston seals lose compression, the pump cannot maintain a consistent output. Replacing the packings or rebuilding the entire fluid section resolves most pressure-related issues.

This issue is often caused by an obstruction or failure in the Bleed Valve Assembly or suction components. The pump may not be priming due to blocked valves, damaged check balls, or worn O-rings. Inspect and replace these parts to restore proper suction and flow.

A hydraulic leak typically indicates worn seals or internal damage in the PowrBeast 9700 hydraulic motor. Over time, hydraulic seals degrade and lose their ability to maintain pressure. Replacing the seal kit or the entire motor assembly prevents overheating and performance loss.

Persistent clogging often means that the High-Pressure Filter (0537220A) is damaged, contaminated, or overdue for replacement. A clogged filter cannot catch debris before it reaches the spray tip, leading to repeated blockages. A new filter restores proper material flow.

If the sprayer struggles to regulate pressure, stalls intermittently, or fails to maintain a consistent spray pattern, the PowrBeast 9700 solenoid assembly may be failing. Solenoids can weaken over time due to heat and heavy use. Replacement is recommended when electrical or pressure-switching issues occur.