Subcategories

NEW PRODUCTS FOR FEBRUARY - POWRBEAST 7700 (230V), 7700 (GAS)

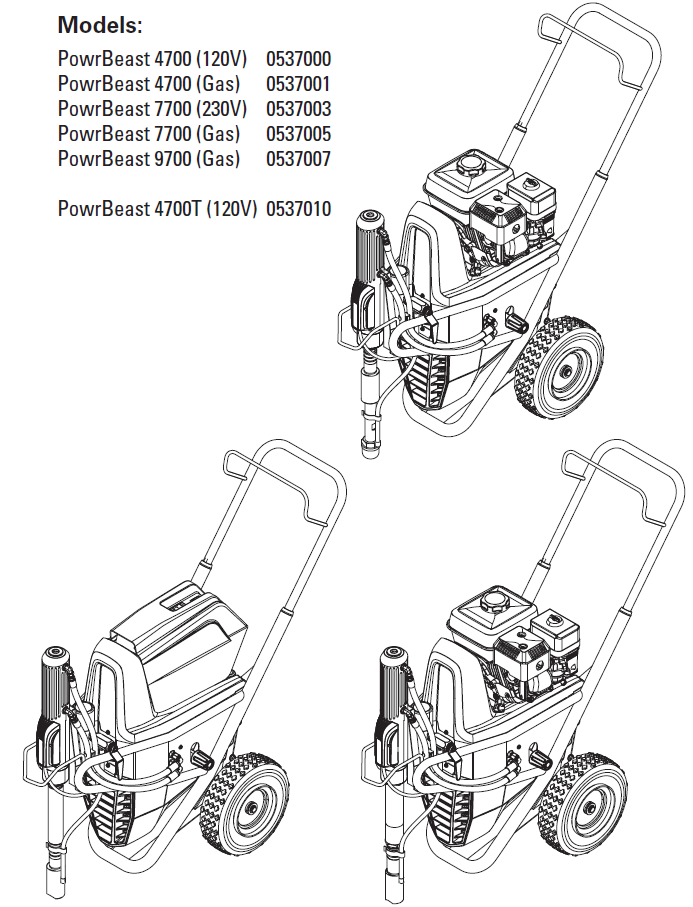

The PowrBeast 7700 (230V) and PowrBeast 7700 (Gas) sprayers are engineered for high-demand, continuous-duty industrial applications. Powered by Titan’s advanced HydraDrive™ hydraulic system, these sprayers deliver exceptional pressure consistency and can handle the toughest materials, including elastomers, heavy primers, block fillers, and high-viscosity coatings.

Designed with a rugged fluid section, robust hydraulic motor, durable high-pressure filtration system, and precision bleed valve assembly, the PowrBeast 7700 ensures superior performance with minimal downtime. At AllTitanParts, you can easily access all replaceable assemblies, including Main Assembly I, Main Assembly II, Hydraulic Motor, Fluid Section (P/N 0537256), High-Pressure Filter (P/N 0537220A), Bleed Valve Assembly, and Cart Assembly to keep your sprayer operating like new.

Pressure loss is often caused by worn packings or a failing piston assembly within the Fluid Section (P/N 0537256). Inspect the piston rod, seals, and compression packings. Replacing these components typically restores full pressure.

A priming failure usually indicates an issue in the Bleed Valve Assembly or the lower fluid section. Air leaks, blocked check valves, or worn O-rings can prevent the pump from priming. Replacing the bleed valve or damaged seals resolves most priming issues.

Leakage from the lower pump section means the internal packings in the Fluid Section are worn out. These packings must be replaced immediately to avoid scoring the piston rod and causing more extensive damage.

The PowrBeast 7700 Hydraulic Motor may overheat due to insufficient hydraulic fluid, internal wear, or restricted flow. Check the hydraulic system for leaks, contamination, or damaged seals. Replacing worn hydraulic components ensures smooth performance.

If you notice reduced flow, frequent tip clogs, or inconsistent spray patterns, the high-pressure filter may be contaminated or its internal components worn. Replacing the filter and O-rings ensures proper material flow and protects the fluid section from debris.